-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

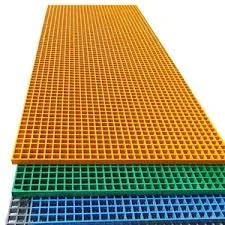

fiberglass customized fittings

The Versatility of Fiberglass Customized Fittings

In today's dynamic industrial landscape, the demand for efficient and durable materials is ever-increasing. One material that has gained significant traction across various sectors is fiberglass. With its remarkable strength-to-weight ratio, corrosion resistance, and versatility, fiberglass has become a favored choice for many applications, particularly in the realm of customized fittings.

What Are Fiberglass Customized Fittings?

Fiberglass customized fittings are tailor-made components designed to meet specific requirements in terms of size, shape, and functionality. These fittings are crafted using fiberglass-reinforced plastics (FRP), which combine the lightweight properties of plastic with the added strength of glass fibers. This unique blend results in fittings that are not only robust but also resistant to a range of environmental challenges, including moisture, chemicals, and high temperatures.

Applications of Fiberglass Customized Fittings

Fiberglass customized fittings are used in a myriad of industries, including construction, automotive, marine, and chemical processing. In the construction industry, these fittings play a crucial role in plumbing and drainage systems, as they provide an effective alternative to traditional metal fittings that are prone to corrosion. Their lightweight nature allows for easier handling and installation, which can lead to significant time and cost savings on construction projects.

In the automotive sector, fiberglass fittings are employed in various components such as engine covers, body panels, and exhaust systems. Their ability to withstand high temperatures and harsh chemicals makes them an ideal choice for parts that require durability and performance. Similarly, in marine applications, fiberglass fittings are used in boat manufacturing, where they provide resilience against saltwater and UV exposure.

The chemical processing industry benefits greatly from fiberglass customized fittings due to their inherent resistance to corrosive substances. These fittings ensure that the integrity of piping systems is maintained, minimizing the risk of leaks and spills that can have severe environmental and financial repercussions.

fiberglass customized fittings

Benefits of Using Fiberglass Customized Fittings

One of the most significant advantages of fiberglass customized fittings is their adaptability. Manufacturers can produce these fittings in various shapes and sizes, allowing for a perfect fit in any application. This customization capability ensures that specific operational needs are met, enhancing system efficiency and functionality.

Another noteworthy benefit is the longevity of fiberglass fittings. The durability of fiberglass means that these components have a significantly longer lifecycle compared to counterparts made from other materials. This extended lifespan reduces the frequency of replacements and maintenance, which can lead to substantial cost savings in the long run.

Additionally, fiberglass fittings are lightweight, making them easier to transport and install. This characteristic not only simplifies the logistics of moving materials but also reduces labor costs associated with installation. The ease of handling fiberglass also minimizes the risk of injury during transportation and assembly.

Sustainability Considerations

As industries worldwide strive for sustainability, fiberglass emerges as an eco-friendlier option. Many manufacturers are now producing fiberglass fittings using recycled materials, which contributes to reduced waste and a smaller carbon footprint. Moreover, the longevity of fiberglass products means less frequent replacements, leading to decreased resource consumption over time.

Conclusion

Fiberglass customized fittings represent a blend of innovation and practicality in the modern manufacturing landscape. Their versatility, durability, and resistance to environmental factors make them a preferred choice for various industries. As the demand for customized solutions continues to grow, the importance of fiberglass fittings will undoubtedly rise, offering businesses an effective way to enhance their operational efficiency while contributing to sustainable practices. Whether in construction, automotive, marine, or chemical processing, the potential applications for fiberglass customized fittings are extensive, and their benefits are undeniable.