-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

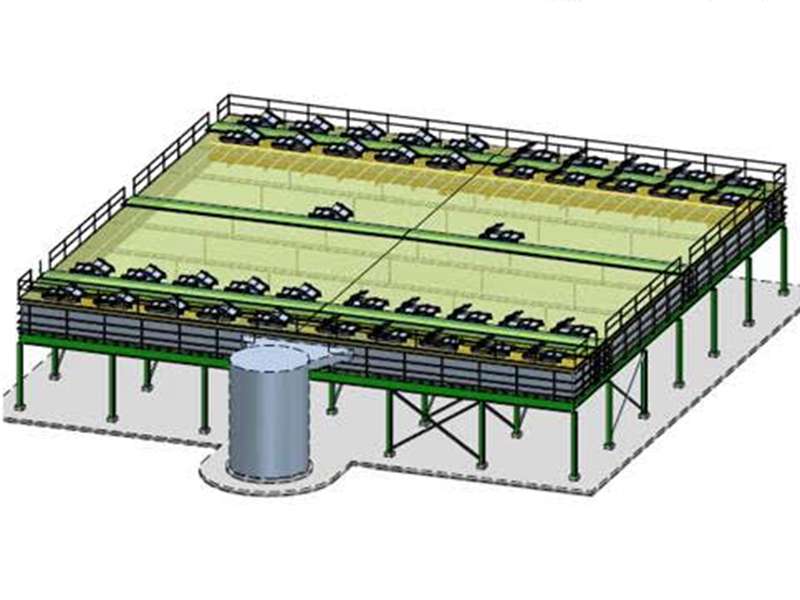

fiberglass damper

Understanding Fiberglass Dampers Their Importance and Applications

Fiberglass dampers are innovative devices designed to control the flow of air and manage sound within various systems. Made from reinforced fiberglass materials, these dampers serve crucial roles in various industries, including HVAC (Heating, Ventilation, and Air Conditioning), automotive, and manufacturing. Their lightweight nature, durability, and resistance to corrosion make fiberglass dampers a preferred choice for many applications.

One of the primary functions of fiberglass dampers is to regulate airflow in ventilation systems. By adjusting the damper position, engineers can optimize air distribution throughout a building, ensuring that each room receives the necessary amount of conditioned air. This regulation not only contributes to comfort but also enhances energy efficiency. In industries where precise temperature control is vital, such as food processing or pharmaceuticals, fiberglass dampers are invaluable for maintaining strict environmental parameters.

Another significant application of fiberglass dampers is in noise control. In many industrial settings, excessive noise can lead to a challenging work environment and even affect workers' health and productivity. Fiberglass dampers can be designed to attenuate sound by absorbing certain frequencies and reducing overall noise levels. This capability is particularly beneficial in power plants, factories, and other facilities where machinery operations generate high decibel levels.

fiberglass damper

In addition to their functional benefits, fiberglass dampers are also highly resistant to chemicals and moisture, which makes them suitable for use in humid or corrosive environments. This resistance helps to extend the lifespan of the equipment, thereby reducing maintenance costs and downtime. Compared to traditional metal dampers, fiberglass dampers do not suffer from rust or degradation, ensuring reliable performance over time.

The installation of fiberglass dampers is relatively straightforward, which provides additional convenience for engineers and technicians. Their lightweight design allows for easier handling and reduces the overall labor costs associated with installation. Furthermore, the flexibility in design enables manufacturers to customize dampers according to specific requirements, ensuring they meet the unique challenges of each application.

Environmental sustainability is another aspect drawing attention to fiberglass dampers. As industries worldwide move toward greener practices, the use of non-toxic, recyclable fiberglass aligns with the goals of reducing environmental impact. Utilizing fiberglass dampers can significantly lower energy consumption and greenhouse gas emissions attributable to HVAC systems.

In conclusion, fiberglass dampers play a crucial role in modern engineering and industrial applications by providing efficient airflow control, noise reduction, and chemical resistance. Their lightweight nature and durability further enhance their appeal across various sectors. As the push for sustainability intensifies, fiberglass dampers will likely become even more prominent, helping industries achieve their operational goals while adhering to environmental standards. Investing in fiberglass dampers is not merely a choice of material; it's a strategic move toward a more efficient and sustainable future in many aspects of industrial and commercial operations.