-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Feb . 01, 2025 01:08

Back to list

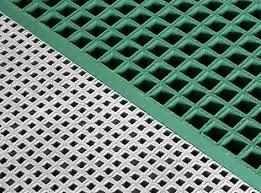

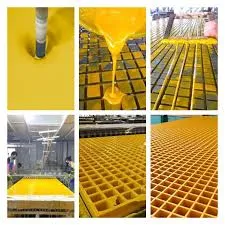

fiberglass demister

Fiberglass demisters are critical components in industrial processes where liquid droplets need to be efficiently separated from gas streams. The importance of these devices in ensuring optimal performance, safety, and compliance with environmental regulations cannot be overstated. With advancements in technology, fiberglass demisters have evolved to offer enhanced performance and reliability.

Building trust in fiberglass demisters also involves field validation and regular performance audits. Industries employing these demisters often undertake rigorous testing to ensure they maintain their separation efficiency over time. Incorporating real-time monitoring systems can further enhance trust by enabling predictive maintenance schedules. Detecting early signs of demister degradation or blockages ensures continuity in operations and prevents costly unscheduled downtimes. Moreover, expert recommendations often suggest integrating fiberglass demisters with automated systems for periodic cleaning, ensuring they remain free of particulates that could impede their function. Such integration reflects a sound strategy for maintaining peak demister performance and extending their lifespan. Fiberglass demisters also support environmental sustainability by reducing emissions of harmful aerosols into the atmosphere. By capturing even the finest droplets from exhaust gases, these demisters help industries comply with stringent environmental norms, providing an eco-friendly solution for gas cleaning. The emphasis on green technology underscores the credibility of fiberglass demisters as a future-ready choice for industries aiming to reduce their environmental footprint. To conclude, the role of fiberglass demisters extends beyond mere liquid-gas separation; they are pivotal in enhancing process safety, efficiency, and environmental compliance. Their deployment is a testament to advanced engineering and reliable performance rooted in decades of industry research and development. For businesses aiming to optimize their separation processes, investing in high-quality, expertly designed fiberglass demisters is a decision backed by both empirical evidence and field expertise.

Building trust in fiberglass demisters also involves field validation and regular performance audits. Industries employing these demisters often undertake rigorous testing to ensure they maintain their separation efficiency over time. Incorporating real-time monitoring systems can further enhance trust by enabling predictive maintenance schedules. Detecting early signs of demister degradation or blockages ensures continuity in operations and prevents costly unscheduled downtimes. Moreover, expert recommendations often suggest integrating fiberglass demisters with automated systems for periodic cleaning, ensuring they remain free of particulates that could impede their function. Such integration reflects a sound strategy for maintaining peak demister performance and extending their lifespan. Fiberglass demisters also support environmental sustainability by reducing emissions of harmful aerosols into the atmosphere. By capturing even the finest droplets from exhaust gases, these demisters help industries comply with stringent environmental norms, providing an eco-friendly solution for gas cleaning. The emphasis on green technology underscores the credibility of fiberglass demisters as a future-ready choice for industries aiming to reduce their environmental footprint. To conclude, the role of fiberglass demisters extends beyond mere liquid-gas separation; they are pivotal in enhancing process safety, efficiency, and environmental compliance. Their deployment is a testament to advanced engineering and reliable performance rooted in decades of industry research and development. For businesses aiming to optimize their separation processes, investing in high-quality, expertly designed fiberglass demisters is a decision backed by both empirical evidence and field expertise.

Next:

Related Products