-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

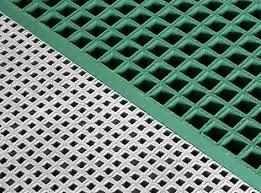

fiberglass dual lamination

The Benefits and Applications of Fiberglass Dual Lamination

Fiberglass dual lamination is an innovative technique that combines two layers of fiberglass with a resin system to enhance the properties of the material, resulting in a product that boasts improved durability, corrosion resistance, and overall structural integrity. This method is becoming increasingly popular across various industries, including construction, marine, automotive, and manufacturing.

One of the primary benefits of fiberglass dual lamination is its notable strength-to-weight ratio. It offers high tensile strength without the added weight typical of traditional materials like steel or aluminum. This characteristic makes it an excellent choice for applications where minimizing weight is crucial without sacrificing performance. For instance, in the aerospace industry, lightweight composite materials improve fuel efficiency and performance.

In addition to its remarkable strength, fiberglass dual lamination provides exceptional resistance to environmental factors

. The layered structure effectively protects against moisture, chemicals, and UV radiation, making it suitable for outdoor applications, such as roofing materials and marine vessels. The longevity of fiberglass in harsh conditions reduces maintenance costs and extends the lifespan of the product, providing a sustainable option for manufacturers and consumers alike.fiberglass dual lamination

The dual lamination process also allows for customization in the type of resin used, enabling the material to meet specific requirements of various applications. For example, different resin formulations can improve flexibility, impact resistance, or thermal stability, catering to the unique needs of each project. This versatility makes fiberglass dual lamination appealing for a wide range of products, from automotive components to construction materials and beyond.

Another significant advantage is the aesthetic potential of fiberglass dual lamination. Manufacturers can incorporate various colors and finishes into the lamination process, resulting in visually appealing products that do not compromise on functionality. This quality makes it an attractive choice for consumer goods where appearance is as crucial as performance, such as furniture or ornamental features in architecture.

Moreover, the sustainability of fiberglass materials is gaining traction. With the increased focus on eco-friendly practices, many manufacturers are now employing recycled fiberglass in their dual lamination processes. This not only reduces waste but also lessens the environmental footprint associated with the production of new materials.

In conclusion, fiberglass dual lamination represents a significant advancement in material science, offering a range of benefits that cater to diverse industries. Its strength, resistance to environmental factors, customization potential, aesthetic appeal, and sustainability make it a compelling choice for modern applications. As technology continues to evolve, it is likely that fiberglass dual lamination will play an even more prominent role in the development of innovative products that meet the demands of the 21st century.