-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

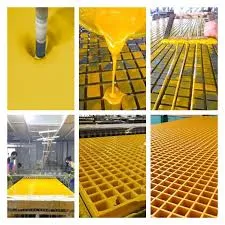

fiberglass dual lamination product

Understanding Fiberglass Dual Lamination Products

In recent years, the demand for versatile and durable materials in various industries has increased significantly. One such material that has gained popularity is fiberglass dual lamination products. This innovative solution offers a combination of strength and flexibility, making it ideal for a wide range of applications, from construction and transportation to electronics and marine environments.

Fiberglass dual lamination refers to a process where two layers of fiberglass are bonded together with a resin, creating a composite material that boasts enhanced properties. The outer layer typically serves as a protective shield against environmental factors, while the inner layer adds structural integrity. This dual-layer approach not only strengthens the material but also significantly improves its resistance to moisture, chemicals, and temperature fluctuations.

One of the key advantages of fiberglass dual lamination products is their lightweight nature. Unlike traditional materials such as metal or wood, fiberglass offers a high strength-to-weight ratio, making it easier to handle and install. This characteristic is particularly beneficial in industries such as aerospace and automotive, where reducing weight is crucial for improving fuel efficiency and overall performance.

Moreover, the flexibility of fiberglass allows it to be molded into various shapes and sizes, accommodating unique design specifications. This adaptability makes it a popular choice for custom applications in architecture and interior design. For instance, fiberglass dual lamination can be used to create complex structures, such as curved walls or ornamental features, without compromising strength or durability.

fiberglass dual lamination product

In addition to its mechanical properties, fiberglass is also renowned for its resistance to corrosion and decay. This quality is especially valuable in applications exposed to harsh environments, such as marine vessels and chemical processing facilities. By utilizing fiberglass dual lamination products, industries can reduce maintenance costs and extend the lifespan of their structures and equipment.

The manufacturing process of fiberglass dual lamination involves several steps, including the selection of appropriate fiberglass materials, the application of resin, and curing to achieve optimal strength. Skilled technicians meticulously oversee this process to ensure the final product meets strict quality standards. Advanced technology and techniques, such as vacuum infusion and filament winding, further enhance the manufacturing efficiency and product performance.

Environmentally conscious consumers and manufacturers are increasingly turning to fiberglass dual lamination products due to their sustainability characteristics. Many fiberglass materials are recyclable, and the production processes are becoming more energy-efficient. Additionally, the durability and long lifespan of these products contribute to a reduced need for replacements and waste, making them an eco-friendly choice.

In conclusion, fiberglass dual lamination products represent a significant advancement in material science, offering a unique combination of durability, flexibility, and resistance to various environmental challenges. Their lightweight nature and adaptability make them suitable for a wide range of applications across multiple industries. As technology continues to evolve, we can expect even more innovative developments in fiberglass products that will further enhance their utility and sustainability. Whether for industrial applications or creative designs, fiberglass dual lamination stands at the forefront of modern material solutions, paving the way for a more efficient and environmentally friendly future.