-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

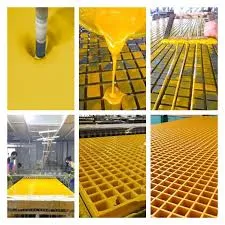

fiberglass dual lamination product

The Advantages of Fiberglass Dual Lamination Products

In modern manufacturing and construction, materials play a pivotal role in ensuring durability, strength, and longevity. Among these materials, fiberglass dual lamination has emerged as a leading option in various applications, thanks to its versatility and exceptional properties. This article explores the benefits and applications of fiberglass dual lamination products, shedding light on why they have become a preferred choice in diverse industries.

Fiberglass dual lamination refers to a manufacturing process that combines fiberglass layers with a resin matrix, creating a robust and durable composite material. This dual lamination technique enhances the structural integrity of the product by providing increased strength and resistance to environmental factors. The process involves layering fiberglass cloths, which are then saturated with resin and cured to form a solid, cohesive structure. The result is a lightweight yet exceptionally strong material that can withstand considerable mechanical stress.

One of the primary advantages of fiberglass dual lamination products is their resistance to corrosion. Unlike traditional metals, which can corrode when exposed to moisture and chemicals, fiberglass composites offer superior resistance to corrosion, making them ideal for use in harsh environments. This property is particularly beneficial in industries such as marine, chemical processing, and wastewater treatment, where materials are frequently exposed to aggressive substances.

In addition to their corrosion resistance, fiberglass dual lamination products exhibit impressive thermal and electrical insulation properties. This makes them suitable for applications in electrical enclosures, insulators, and components that require thermal stability under varying conditions. The ability to maintain performance and integrity across a wide range of temperatures further enhances the versatility of these composites.

fiberglass dual lamination product

Moreover, the aesthetic appeal of fiberglass dual lamination products cannot be overlooked. They can be manufactured in a variety of colors and finishes, allowing for customization that meets both functional and aesthetic requirements. This flexibility makes them popular in the automotive, consumer goods, and architectural industries, where visual design is as crucial as performance.

Another significant benefit of fiberglass dual lamination is its lightweight nature. This characteristic facilitates easier handling, transportation, and installation compared to traditional building materials like steel or concrete. The reduction in weight not only lowers shipping costs but also minimizes the structural load on buildings, thereby enhancing overall engineering efficiency.

The sustainability aspect of fiberglass products is also worth noting. Many manufacturers are now employing eco-friendly resins and additives, making fiberglass dual lamination an environmentally conscious choice. With growing awareness about sustainable practices, industries are increasingly turning towards materials that not only perform well but also minimize environmental impact.

In conclusion, fiberglass dual lamination products offer a multitude of advantages that make them a superior choice across various applications and industries. Their strength, corrosion resistance, thermal stability, and aesthetic customization combine to create a material that meets modern engineering demands. As manufacturers continue to innovate and improve the production techniques of fiberglass composites, we can expect to see even broader applications and advancements in this area, reinforcing fiberglass dual lamination’s position as a vital material in contemporary manufacturing and construction.