-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

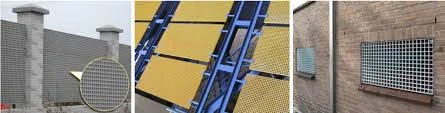

fiberglass duct corrosion resistance

Fiberglass Duct Corrosion Resistance An Overview

Fiberglass ducts have gained prominent recognition in various industrial applications due to their exceptional corrosion resistance properties. Unlike traditional metal ducting systems, which are susceptible to rust and degradation in hostile environments, fiberglass offers an innovative solution, ensuring longevity and reliability in air handling systems.

Understanding Corrosion in Duct Systems

Corrosion is a natural process that deteriorates materials through electrochemical reactions with the environment. In ducting systems, factors such as moisture, chemical exposure, and temperature fluctuations can significantly accelerate this process. Metals, particularly ferrous materials, are highly vulnerable to corrosion, which can lead to reduced airflow, increased maintenance costs, and, ultimately, system failure. This is where fiberglass ducts shine, as they are fundamentally engineered to withstand corrosive conditions.

Properties of Fiberglass Ducts

Fiberglass is a composite material made of fine glass fibers and resin. This combination endows it with unique properties that make it an ideal choice for duct systems. The primary advantage lies in its inertness to many corrosive substances, including acids, alkalis, and solvents. As a result, fiberglass ducts can perform reliably in environments with high humidity and aggressive chemicals—conditions that would typically compromise metal ducts.

fiberglass duct corrosion resistance

Additionally, fiberglass ducts are lightweight, which simplifies installation and reduces labor costs. Their smooth internal surfaces promote efficient airflow, minimizing energy loss and improving overall system efficiency. These attributes make fiberglass a cost-effective alternative in both the short and long term.

Applications and Benefits

The industries that benefit most from fiberglass duct systems include chemical processing, wastewater treatment, food processing, and any other sector where moisture and corrosive elements are prevalent. In these environments, the durability of fiberglass ducts translates into reduced downtime and maintenance expenses, as they do not require regular painting or treatment that metal systems typically necessitate.

Moreover, fiberglass ducts are less likely to foster mold and bacteria growth due to their smooth surfaces and non-porous nature. This feature is particularly crucial in settings like hospitals and food facilities, where air quality and hygiene are paramount.

Conclusion

In conclusion, fiberglass duct systems stand out as a superior choice when it comes to addressing corrosion-related challenges in various industrial applications. Their resistance to chemical degradation, coupled with additional benefits such as lightweight construction and energy efficiency, solidifies their position in modern ductwork solutions. Investing in fiberglass ducts not only enhances operational efficacy but also contributes to long-term savings, making it a smart choice for industries aiming to future-proof their infrastructure against the ravages of corrosion. As technology continues to advance, the relevance of fiberglass in duct systems will likely grow, paving the way for safer and more reliable industrial operations.