-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

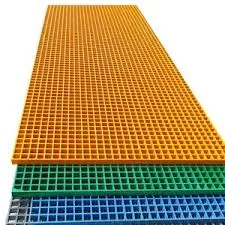

fiberglass duct corrosion resistance

The Corrosion Resistance of Fiberglass Ducts

In various industrial applications, the efficiency, longevity, and reliability of ductwork systems are crucial. One material that has been gaining popularity due to its excellent performance characteristics is fiberglass. Comprising a composite of glass fibers and a synthetic resin, fiberglass ducts offer an array of advantages, particularly in terms of corrosion resistance.

Understanding Corrosion and Its Implications

Corrosion occurs when materials, typically metals, react with environmental elements such as moisture, air, and chemicals. This degradation can lead to failures in duct systems, resulting in down-time, costly repairs, and operational inefficiencies. In environments where corrosive substances are present—like chemical plants, wastewater treatment facilities, and oil refineries—the threat of corrosion is notably high. Even in less aggressive environments, standard materials can still face deterioration over time.

The Advantages of Fiberglass Ducts

Fiberglass ducts are inherently resistant to corrosion, making them an ideal choice for harsh conditions. Unlike traditional metal ductwork, which can rust or corrode, fiberglass does not react with most chemicals. This characteristic means that fiberglass ducts can withstand exposure to acids, bases, and salts, which would typically lead to metal deterioration.

Moreover, fiberglass ducts are lightweight, which simplifies installation and minimizes structural load. Their non-conductive properties contribute to energy efficiency by reducing heat loss during air transfer. This characteristic not only improves the energy efficiency of HVAC systems but also lowers operational costs over time.

Applications and Industries Benefiting from Fiberglass Ducts

fiberglass duct corrosion resistance

Industries that handle corrosive materials or operate in extreme conditions can significantly benefit from the use of fiberglass duct systems. Chemical processing facilities often utilize fiberglass ducts to transport corrosive vapors and gases safely. In wastewater treatment plants, the ability to withstand aggressive chemicals ensures the longevity and reliability of the system, which is vital for maintaining public health and environmental standards.

Additionally, fiberglass ducts are found in food processing facilities where hygiene is paramount. Their smooth surface prevents the buildup of contaminants, facilitating easier cleaning and maintenance. This not only meets health regulations but also ensures product safety and quality.

Comparative Analysis with Other Materials

When comparing fiberglass ducts to other materials, such as aluminum or galvanized steel, the advantages become clear. Steel ducts are susceptible to rust and corrosion, especially when exposed to moisture. Although coatings can be applied to provide some level of protection, these are not foolproof and can wear off over time. On the other hand, aluminum may corrode under certain conditions and is generally less robust compared to fiberglass.

In terms of cost, while fiberglass ducts may have a higher initial investment, their longevity and reduced maintenance needs often lead to lower overall lifecycle costs. This economic sustainability, combined with their superior performance characteristics, makes fiberglass a compelling option.

Conclusion

The corrosion resistance of fiberglass ducts positions them as a superior alternative to traditional duct materials in various challenging applications. Their ability to withstand harsh environmental conditions, coupled with their lightweight, energy-efficient characteristics, makes them an ideal choice for many industries. As organizations seek to improve operational efficiency and longevity of their duct systems, the use of fiberglass ducts is becoming increasingly prevalent. Investing in corrosion-resistant ductwork is not just a matter of immediate advantage; it signifies a commitment to reliability, efficiency, and safety in industrial operations.