-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Corrosion Resistance of Fiberglass Ducts for Enhanced Performance and Durability

Understanding the Corrosion Resistance of Fiberglass Ducts

In industries where air distribution systems are crucial, the materials used in ductwork play a pivotal role in ensuring operational efficiency and longevity. Among these materials, fiberglass ducts have gained considerable attention for their superior properties, particularly their corrosion resistance. This characteristic not only enhances the longevity of these systems but also ensures they perform effectively in a variety of challenging environments.

What is Corrosion Resistance?

Corrosion resistance refers to the ability of a material to withstand degradation due to chemical reactions with its environment. For duct systems, this usually means combating the effects of moisture, chemicals, and temperature fluctuations. Traditional duct materials, such as metal, are often vulnerable to rust and corrosion, which can compromise their integrity over time. Consequently, the development of fiberglass ducts has emerged as an innovative solution to address these concerns.

Advantages of Fiberglass Ducts

1. Chemical Resistance Fiberglass ducts are inherently resistant to a range of chemicals. This resistance makes them particularly suitable for industrial applications, such as chemical processing plants, where exposure to corrosive substances is commonplace. Unlike metals that can corrode when exposed to acids and alkalis, fiberglass maintains its structural integrity in these hostile environments.

2. Moisture Resistance In environments with high humidity or where condensation is a regular occurrence, moisture resistance is crucial. Fiberglass does not oxidize like metal, making it immune to rust formation. This property helps in maintaining clean air quality as it reduces the growth of mold and bacteria within the duct system, essential for industries that prioritize hygiene, such as pharmaceuticals and food processing.

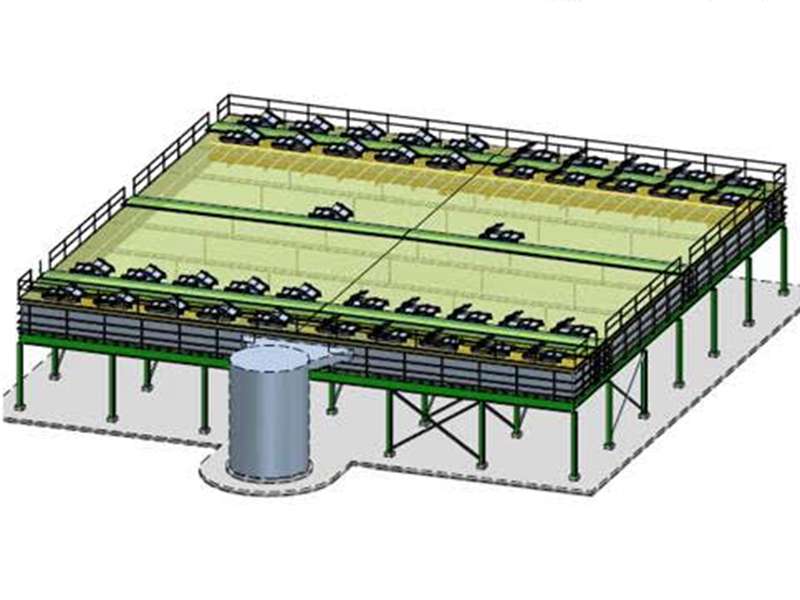

fiberglass duct corrosion resistance

3. Lightweight and Versatile Fiberglass ducts are significantly lighter than traditional metal ducts. This lightweight nature simplifies installation, reduces labor costs, and minimizes structural support requirements. Additionally, fiberglass can be molded into various shapes and sizes, making it adaptable for different applications with complex layouts.

4. Insulation Properties Fiberglass ducts provide excellent thermal insulation. This insulation not only aids in energy efficiency but also minimizes the risk of condensation occurring on the exterior surface of the ducts. By preventing the formation of water droplets, they further enhance corrosion resistance in condensation-prone installations.

Applications of Fiberglass Ducts

The advantages of fiberglass ducts have led to their wide application across various industries. In the aerospace field, manufacturers utilize fiberglass for its lightweight and non-corrosive properties, allowing for efficient air management in aircraft. Similarly, in the marine industry, fiberglass ducts find use in ships and boats, where exposure to saltwater can be detrimental to traditional duct materials. Moreover, in the construction sector, fiberglass ducts are increasingly favored for HVAC systems in commercial buildings, ensuring that air quality remains uncompromised over time.

Conclusion

In conclusion, the corrosion resistance of fiberglass ducts makes them an ideal choice for modern air distribution systems across numerous industries. Their ability to withstand chemical attack, prevent moisture accumulation, and offer thermal insulation sets them apart from traditional duct materials. As industries continue to prioritize efficiency, safety, and sustainability, fiberglass ducts will likely play an even greater role in the future of HVAC design and implementation.

Choosing the right duct material is critical for any facility. By opting for fiberglass ducts, businesses can ensure lower maintenance costs, enhanced longevity, and improved operational efficiency. As technology advances, the applications of fiberglass will continue to expand, further solidifying its position as a leading solution in the fight against corrosion in duct systems.