-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

fiberglass ducts demonstrate exceptional resistance against

Exceptional Resistance of Fiberglass Ducts

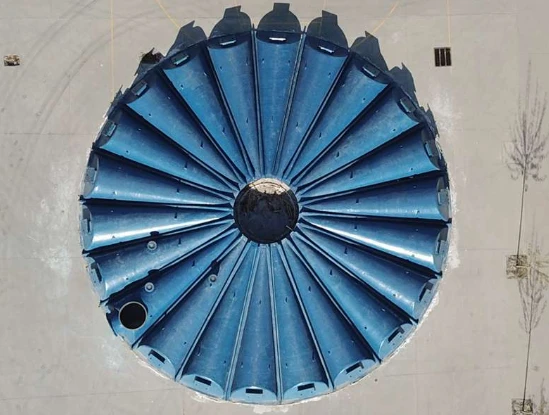

Fiberglass ducts have steadily gained popularity in the construction and HVAC (heating, ventilation, and air conditioning) industries due to their exceptional resistance against various environmental and operational challenges. With the increasing demand for energy-efficient and durable materials, fiberglass offers an array of benefits that make it a superior choice for ductwork systems. This article will explore the numerous advantages of fiberglass ducts, focusing on their resistance to corrosion, thermal management, fire, and installation flexibility.

Corrosion Resistance

One of the most significant advantages of fiberglass ducts is their remarkable resistance to corrosion. Conventional duct materials, such as metal, can suffer from rust and degradation when exposed to moisture and a variety of chemicals. In contrast, fiberglass is inherently resistant to these issues, which stems from its composition. Made from a combination of glass fibers and synthetic resins, fiberglass ducts do not corrode, reducing the likelihood of mold growth and the release of harmful particles into the air. This characteristic is particularly important in industries such as food processing, pharmaceuticals, and chemical manufacturing, where air quality and hygiene are paramount.

Thermal Efficiency

Fiberglass ducts are also lauded for their excellent thermal insulation properties. The material is a poor conductor of heat, which means it minimizes heat loss or gain during the transportation of heated or cooled air. This thermal efficiency can lead to lower energy bills and a reduced carbon footprint, making it an environmentally friendly choice. In a world increasingly focused on sustainability, fiberglass ducts stand out as a responsible solution for managing energy in commercial and residential buildings alike.

Fire Resistance

fiberglass ducts demonstrate exceptional resistance against

While it might be surprising to some, fiberglass ducts possess inherent fire resistance. The core material does not support combustion, and many manufacturers enhance this property by treating the ducts with additional fire-retardant agents. In the event of a fire, the use of fiberglass ducts can help contain the spread of flames and smoke, offering crucial time for occupants to evacuate and for emergency responders to tackle the situation. This fire safety feature is especially valuable in high-rise buildings, hospitals, and places of assembly, where tight regulations and safety protocols dictate the use of non-combustible materials.

Installation Flexibility

Another attractive aspect of fiberglass ducts is their versatility in installation. Unlike heavier metal ducts, fiberglass is lightweight and easy to handle, significantly reducing labor costs and installation time. The flexibility of fiberglass also allows for more intricate designs and layouts, enabling contractors to navigate around obstacles more easily. This adaptability is particularly beneficial in retrofitting projects, where existing structures pose challenges to traditional ductwork installation. Fiberglass ducts can be custom-manufactured to fit a variety of applications, ensuring optimal performance no matter the configuration.

Conclusion

In conclusion, fiberglass ducts demonstrate exceptional resistance against numerous challenges characterized by corrosion, thermal inefficiencies, fire hazards, and installation complexities. As the HVAC industry evolves to meet the growing demands for sustainable and efficient solutions, fiberglass ducts emerge as a prominent choice for building systems. Their impressive durability and resistance properties not only ensure a long-lasting product but also contribute to a healthier and safer indoor environment.

Investing in fiberglass duct systems means choosing a reliable option that aligns with both current building codes and the future of energy-efficient HVAC solutions. As we continue to push for innovative materials in construction and engineering, fiberglass ducts certainly hold a prominent place in shaping our built environment for years to come.