-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

fiberglass fan

Understanding Fiberglass Fans Applications, Benefits, and Maintenance

In the realm of industrial and commercial ventilation, fiberglass fans have emerged as a pivotal solution for various airflow and cooling needs. These specialized fans are crafted from fiberglass-reinforced materials that offer distinct advantages over traditional metal or plastic fans. This article delves into the unique characteristics, applications, benefits, and maintenance of fiberglass fans to provide a comprehensive overview of their importance in various industries.

What is a Fiberglass Fan?

Fiberglass fans are ventilation devices constructed primarily from fiberglass, a composite material made from fine glass fibers and resin. This composition provides several benefits, including resistance to corrosion, lightweight characteristics, and mechanical strength. Fiberglass fans can be designed in various configurations, including axial and centrifugal designs, to meet specific application needs. Their ability to perform reliably in harsh environmental conditions sets them apart from conventional fans.

Applications of Fiberglass Fans

1. Chemical and Pharmaceutical Industries One of the most significant applications of fiberglass fans is in environments where corrosive substances are present, such as in chemical processing plants. These fans are ideal for managing fume and vapor exhaust, ensuring that harmful air pollutants are effectively ventilated.

2. Water and Wastewater Treatment In wastewater treatment facilities, fiberglass fans play a crucial role in aeration processes and odor control. Their durability and resistance to chemicals enable them to handle the demands of varying water conditions, making them indispensable in this sector.

3. Food Processing The food industry requires stringent hygiene standards. Fiberglass fans contribute to maintaining clean air by minimizing the risk of contamination. They can withstand frequent cleaning and exposure to moisture without deteriorating, ensuring a reliable ventilation solution.

4. Mining and Heavy Manufacturing Fiberglass fans are utilized in mining operations to provide ventilation in underground environments. Their capacity to operate in dusty or gritty conditions without rusting or corroding makes them suitable for the harsh realities of mining. Additionally, heavy manufacturing facilities benefit from fiberglass fans for their ability to combat high levels of heat and humidity.

Benefits of Using Fiberglass Fans

1. Corrosion Resistance Unlike metal fans, fiberglass fans do not corrode when exposed to moisture, chemicals, or other corrosive elements. This property significantly extends their lifespan and reduces the need for repairs or replacements.

fiberglass fan

2. Lightweight Design Fiberglass fans are lightweight, making them easier to transport and install compared to their metal counterparts. This feature can lead to lower installation costs and reduced structural support requirements.

3. Energy Efficiency With advanced designs and materials, fiberglass fans can operate efficiently while consuming less power. This energy-saving capability translates into lower operating costs over time.

4. Customizable Options Fiberglass fans can be tailored to meet specific operational requirements. They can be manufactured in various sizes and configurations, allowing for flexibility in design to optimize airflow in different settings.

Maintenance of Fiberglass Fans

To ensure the longevity and efficiency of fiberglass fans, regular maintenance is essential. Here are some recommended practices

1. Routine Inspections Conduct regular inspections to check for any signs of wear, damage, or buildup of contaminants. Early detection of issues can prevent more significant problems.

2. Cleaning Regularly clean the fan blades and housing to remove dust and debris that may impede performance. Use non-abrasive cleaners to avoid damaging the fiberglass surface.

3. Lubrication Check and lubricate moving parts as necessary, depending on the specific design and manufacturer's recommendations.

4. Operational Checks Monitor the fan's operation for unusual noises or vibrations, which may indicate underlying issues that require attention.

In conclusion, fiberglass fans represent a perfect blend of durability, efficiency, and versatility, making them a critical asset in numerous industrial applications. Their unique properties allow them to excel in environments that challenge conventional fan designs. As industries continue to evolve, the demand for reliable and effective ventilation solutions like fiberglass fans will only increase, underscoring their importance in maintaining air quality and operational efficiency.

Latest news

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

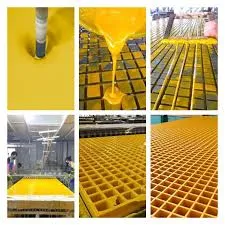

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025