-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Jan . 31, 2025 06:18

Back to list

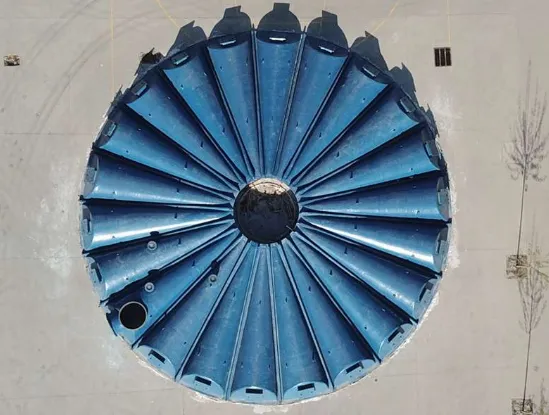

Fans & Dampers & Demisters

Fiberglass flanges have become a pivotal component in various industries due to their unique properties and adaptability. As more sectors shift towards materials that offer durability and versatility, fiberglass emerges as a top choice. It is essential to understand the multifaceted benefits and applications of fiberglass flanges to appreciate their contribution to modern industrial needs.

From an engineering perspective, the ease of fabrication and installation of fiberglass flanges is noteworthy. These flanges can be custom-molded to meet specific size and design requirements, offering flexibility that is not always possible with metals. The lightweight nature also simplifies the installation process, reducing time and labor costs significantly. The environmental benefits of fiberglass flanges cannot be understated. Unlike metals, which can contribute to environmental degradation through mining and rust, fiberglass offers a more sustainable alternative. Its longevity and minimal maintenance reduce the need for frequent replacements, thus limiting waste. Additionally, many fiberglass products can be recycled, aligning with global sustainability goals. Investing in fiberglass flanges is a decision backed not only by technical superiority but by economic efficiency as well. The initial cost might be higher compared to some traditional materials, but the long-term savings in maintenance, replacement, and operational efficiency make fiberglass a cost-effective solution. In summary, fiberglass flanges have carved a niche for themselves across various industries due to their unique properties. By offering unmatched strength, corrosion resistance, thermal and electrical insulation, ease of fabrication, and environmental benefits, they meet and exceed the demands of modern industrial applications. Industries looking to enhance performance while cutting down on lifetime costs would do well to consider fiberglass flanges as a strategic investment. As technology progresses, fiberglass flanges are poised to remain a cornerstone component, shaping the future of industrial materials.

From an engineering perspective, the ease of fabrication and installation of fiberglass flanges is noteworthy. These flanges can be custom-molded to meet specific size and design requirements, offering flexibility that is not always possible with metals. The lightweight nature also simplifies the installation process, reducing time and labor costs significantly. The environmental benefits of fiberglass flanges cannot be understated. Unlike metals, which can contribute to environmental degradation through mining and rust, fiberglass offers a more sustainable alternative. Its longevity and minimal maintenance reduce the need for frequent replacements, thus limiting waste. Additionally, many fiberglass products can be recycled, aligning with global sustainability goals. Investing in fiberglass flanges is a decision backed not only by technical superiority but by economic efficiency as well. The initial cost might be higher compared to some traditional materials, but the long-term savings in maintenance, replacement, and operational efficiency make fiberglass a cost-effective solution. In summary, fiberglass flanges have carved a niche for themselves across various industries due to their unique properties. By offering unmatched strength, corrosion resistance, thermal and electrical insulation, ease of fabrication, and environmental benefits, they meet and exceed the demands of modern industrial applications. Industries looking to enhance performance while cutting down on lifetime costs would do well to consider fiberglass flanges as a strategic investment. As technology progresses, fiberglass flanges are poised to remain a cornerstone component, shaping the future of industrial materials.

Next:

Related Products