-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Food-Grade Fiberglass Equipment for Safe and Durable Food Handling Solutions

The Importance of Fiberglass Food Grade Equipment in the Food Industry

In the food industry, maintaining high standards of hygiene and safety is paramount. One of the key materials that has gained recognition for its usefulness in food processing and handling is fiberglass. Fiberglass food grade equipment is specifically designed to meet stringent health regulations while providing durability and versatility. This article explores the benefits, applications, and significance of fiberglass food grade equipment in the modern food industry.

Understanding Food Grade Standards

Food grade materials are those that are approved for use in the processing and packaging of food. These materials must meet specific safety standards set by regulatory bodies such as the Food and Drug Administration (FDA) in the United States. Fiberglass, when processed correctly and applied in food-grade applications, is non-toxic, easy to clean, and resistant to various chemical agents, making it an ideal choice for food-grade equipment.

Benefits of Fiberglass Food Grade Equipment

1. Durability Fiberglass is well-known for its durability and strength. It can withstand high levels of stress and strain, making it less prone to damage than other materials such as plastic or metal. This durability translates into a longer lifespan for food grade equipment, which can ultimately save businesses on replacement costs.

2. Corrosion Resistance One of the significant challenges in food processing environments is corrosion. Fiberglass is resistant to many corrosive substances, including acids and alkalis. This resistance helps maintain the integrity of food grade equipment over time, especially in facilities where harsh cleaning chemicals are frequently used.

3. Lightweight Compared to metal alternatives, fiberglass is notably lighter. This attribute not only makes transportation and installation easier but also reduces the energy required for handling during the manufacturing process.

4. Thermal Insulation Fiberglass has excellent insulative properties, which are beneficial in maintaining temperature-controlled environments for food storage and processing. This characteristic is crucial in preventing spoilage and ensuring food safety.

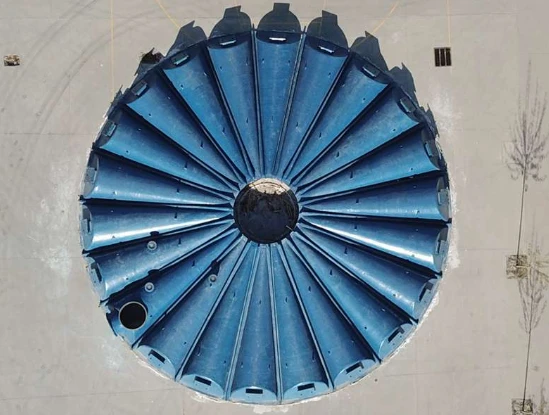

fiberglass food grade equipment

5. Non-Reactive Surface Unlike some metals that can react with certain foods, fiberglass remains inert. This non-reactive nature helps ensure that food products retain their flavor and quality without risk of contamination.

Applications in the Food Industry

Fiberglass food grade equipment finds vast applications within the food industry. Some common uses include

- Storage Tanks Fiberglass is often used to manufacture storage tanks for liquids, including edible oils and other beverages. The non-corrosive nature of fiberglass ensures that stored products remain safe and untainted.

- Conveyor Systems Many food processing plants incorporate fiberglass components into their conveyor systems. Its lightweight yet sturdy nature allows for the smooth transportation of products without risking damage to the materials being moved.

- Tables and Workstations Fiberglass tables and workstations offer durable and easy-to-clean surfaces that meet food safety requirements. These surfaces are resistant to staining and scratching, making them ideal for environments where food is prepared.

- Equipment Casings The casings for refrigeration units, ovens, and other processing equipment can also be made from fiberglass, providing an additional layer of protection against moisture and contamination.

Conclusion

In conclusion, fiberglass food grade equipment plays a crucial role in ensuring food safety and maintaining high hygiene standards in the food industry. Its durability, corrosion resistance, lightweight properties, and non-reactive surface make it an ideal choice for a variety of applications. As the food industry continues to evolve and adapt to new challenges, fiberglass remains a reliable material that meets the stringent requirements of food grade standards. Businesses that utilize fiberglass equipment can ensure they are providing safe, high-quality products to consumers while also benefiting from reduced maintenance and replacement costs. In an industry where safety is of utmost importance, the value of fiberglass food grade equipment cannot be overstated.

Latest news

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025