-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

fiberglass food grade equipment a closer look at its features and ...

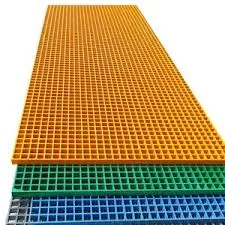

A Closer Look at Fiberglass Food Grade Equipment Features and Benefits

In the food industry, maintaining high standards of hygiene and safety is paramount. One material that has gained popularity for food-grade applications is fiberglass. This composite material, made from fine glass fibers combined with a resin, offers a unique combination of properties that make it ideal for food processing and storage equipment. Here, we will explore the features and benefits of fiberglass food-grade equipment.

Durability and Strength

Fiberglass is renowned for its exceptional strength-to-weight ratio. This means that equipment made from fiberglass is not only lightweight, making it easier to handle and transport, but also incredibly strong and resistant to wear and tear. This durability translates to a longer lifespan for equipment, which is particularly advantageous for food processing operations that require reliable tools to handle heavy loads and continuous usage.

Non-Reactivity and Safety

One of the most critical factors in food handling is the material's reactivity. Fiberglass is chemically inert, meaning it does not react with food substances or produce harmful chemicals that could contaminate food. This non-reactive property ensures that food integrity is maintained, aligning with health regulations and standards in the food industry. As a result, fiberglass food-grade equipment is suitable for a wide variety of applications, including both wet and dry environments.

Ease of Cleaning

fiberglass food grade equipment a closer look at its features and ...

Sanitation is a critical aspect of food processing. Fiberglass surfaces are non-porous, which makes them resistant to water, bacteria, and other contaminants. This characteristic allows for easy cleaning and sanitization, helping facilities meet stringent hygiene standards. Additionally, fiberglass does not corrode or rust, further enhancing its appeal in environments where moisture is prevalent.

Design Flexibility

Another standout feature of fiberglass is its versatility in design. It can be molded into various shapes and sizes, allowing manufacturers to create custom solutions tailored to specific needs within the food industry. This design flexibility can lead to better efficiency in food processing operations, as equipment can be optimized for unique workflows and space constraints.

Cost-Effectiveness

While the initial investment in fiberglass equipment may be higher than some alternatives, its durability and long-term performance often make it more cost-effective over time. The reduced need for frequent replacements and repairs, combined with lower maintenance costs, can lead to significant savings for businesses in the food sector.

In conclusion, fiberglass food-grade equipment offers a compelling combination of strength, safety, hygiene, and versatility. As food industry standards continue to evolve, the advantages of fiberglass make it an attractive option for a variety of applications, contributing to both operational efficiency and food safety.