-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

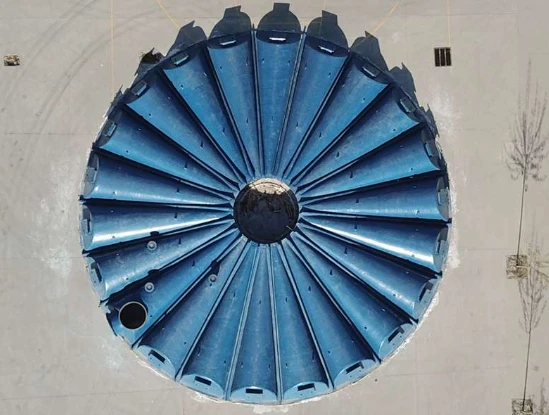

Exploring the Benefits and Characteristics of Food-Grade Fiberglass Equipment for Safety and Efficiency

A Closer Look at Fiberglass Food Grade Equipment Features and Benefits

In the ever-evolving food industry, the materials used in food processing and handling are crucial for maintaining safety, quality, and efficiency. Among these materials, fiberglass food grade equipment has gained prominence due to its unique properties and benefits. This article delves into the features of fiberglass food grade equipment and why it is becoming a preferred choice in many food-related applications.

What is Fiberglass Food Grade Equipment?

Fiberglass food grade equipment is made from reinforced plastic, primarily composed of glass fibers and resin. This combination results in a strong yet lightweight material that is ideal for various applications in food processing, storage, and transportation. The food grade designation indicates that these materials meet strict safety standards set by regulatory bodies to ensure they do not leach harmful substances into food products.

Features of Fiberglass Food Grade Equipment

1. Durability One of the most significant advantages of fiberglass is its robust nature. It can withstand extreme temperatures, chemicals, and mechanical stress without compromising its integrity. This durability makes it suitable for use in various demanding environments, from food manufacturing plants to kitchens.

2. Corrosion Resistance Unlike metal equipment, fiberglass does not rust or corrode when exposed to moisture or harsh cleaning chemicals. This property ensures a longer lifespan and reduced maintenance costs, contributing to more efficient operations.

3. Non-porous Surface Fiberglass has a smooth and non-porous surface, which minimizes the risk of bacterial growth and contamination. This feature is particularly important in the food industry where hygiene is paramount. The easy-to-clean surface allows for thorough sanitation, adhering to health and safety regulations.

4. Lightweight Fiberglass equipment is significantly lighter than metal alternatives, which not only makes it easier to handle and transport but also reduces the strain on storage facilities. This lightweight nature allows for greater flexibility in design and layout within food processing environments.

fiberglass food grade equipment a closer look at its features and ...

5. Versatility Fiberglass is adaptable to a range of products, including tanks, conveyor systems, and trays. Its ability to be molded into various shapes allows manufacturers to customize equipment to meet specific needs, making it a versatile choice across different food sectors.

6. Insulation Properties Fiberglass offers excellent insulation against temperature changes. This feature is particularly important in food preservation, where maintaining consistent temperatures is crucial to prevent spoilage and ensure product quality.

Benefits of Using Fiberglass Food Grade Equipment

1. Enhanced Food Safety The non-porous, easy-to-clean surface and resistance to contamination inherently improve food safety. This quality is essential for any facility aiming to achieve high hygiene standards.

2. Cost-Effective Although the initial investment may be higher than other materials, the durability and low maintenance requirements of fiberglass often lead to significant cost savings over time. The reduced need for repairs and replacements can greatly benefit businesses.

3. Regulatory Compliance Fiberglass food grade equipment typically meets the rigorous standards set by health and safety authorities. This compliance not only protects consumers but also enhances a company's reputation within the industry.

4. Environmental Impact The long lifespan of fiberglass equipment contributes to lower waste generation. Additionally, many manufacturers are now producing fiberglass using environmentally friendly processes, further reducing its ecological footprint.

Conclusion

Fiberglass food grade equipment stands out as a reliable and effective choice for the food processing industry. Its unique combination of durability, safety features, and versatility makes it an ideal material for a range of applications. As food safety regulations continue to evolve and consumer demands for high-quality products increase, the adoption of fiberglass equipment is likely to grow, paving the way for improved operational standards and enhanced food safety practices across the industry.