-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

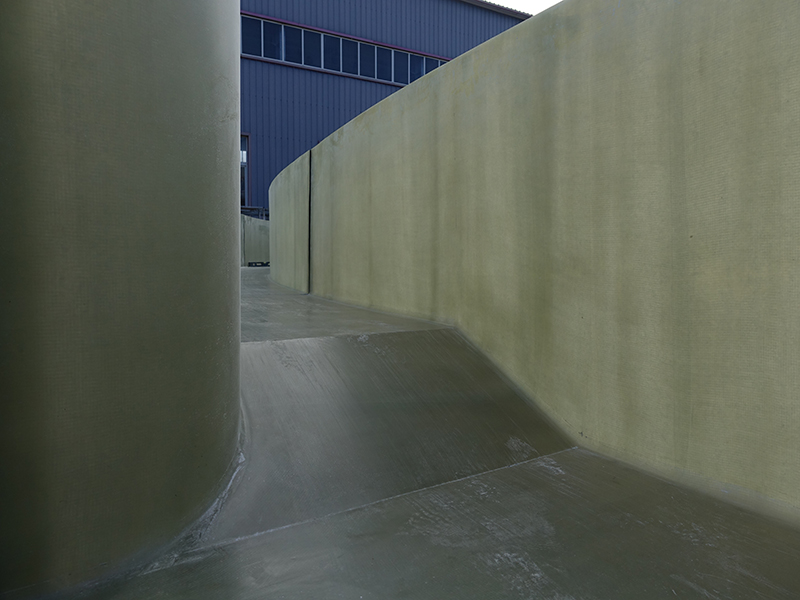

Exploring the Benefits and Features of Food-Grade Fiberglass Equipment in Food Industry

Fiberglass Food Grade Equipment A Closer Look at Its Features and Benefits

In the ever-evolving landscape of food processing and storage, the materials used in production equipment play a crucial role in maintaining the quality and safety of food products. One material that has significantly gained traction in this sector is fiberglass, particularly fiberglass that meets food grade standards. This article delves into the features and benefits of fiberglass food grade equipment, shedding light on why it is becoming a favored choice among industries.

Understanding Food Grade Standards

Food grade standards are established to ensure that materials coming into contact with food products do not pose a risk to health or safety. Fiberglass that is marked as food grade complies with stringent regulations set by organizations such as the FDA, ensuring it is non-toxic and suitable for use in food-related applications. These standards often involve rigorous testing for chemical leaching, mechanical stability, and hygienic properties, which separate food grade fiberglass from regular fiberglass materials.

Key Features of Fiberglass Food Grade Equipment

1. Durability and Strength Fiberglass is known for its exceptional durability. It is resistant to impact, corrosion, and temperature fluctuations, making it an ideal choice for food processing environments where equipment is subjected to various stresses. This resilience not only extends the lifespan of the equipment but also minimizes repair and replacement costs.

2. Lightweight Compared to metals and other traditional materials, fiberglass is considerably lighter. This characteristic facilitates easier installation and transportation, reducing the labor intensity involved in handling and setting up food grade equipment.

3. Non-Reactive One of the most significant advantages of food grade fiberglass is its non-reactive nature. It does not leach harmful substances into food products or react with various food types. This property is essential for maintaining food safety and ensuring that the integrity of the food product remains intact.

fiberglass food grade equipment a closer look at its features and ...

4. Ease of Cleaning Hygienic processing environments are paramount in the food industry. Fiberglass surfaces can be easily cleaned and sanitized, reducing the risk of contamination. The smooth surfaces prevent the buildup of bacteria and other pathogens, aligning with hygiene standards and ensuring compliance during audits.

5. Versatility Fiberglass can be molded into various shapes and sizes, making it suitable for a wide range of applications in food handling, processing, and storage. From storage containers to countertops and equipment, the versatility of fiberglass makes it an adaptable choice in a diverse set of food processing scenarios.

Benefits of Using Fiberglass Food Grade Equipment

1. Cost-Effectiveness Although the initial investment in fiberglass food grade equipment can be higher than some alternatives, its durability and low maintenance costs lead to significant savings in the long run. The longevity and reduced need for frequent replacements translate to lower overall operational costs.

2. Enhanced Safety With rigorous standards in place, fiberglass food grade equipment enhances safety in food processing. The material’s properties ensure that it does not contribute to food contamination, thereby safeguarding public health and fulfilling regulatory requirements.

3. Eco-Friendly Options Many fiberglass manufacturers are now focusing on sustainability. By utilizing recycled materials and adopting eco-friendly production methods, they offer solutions that are not only safe and efficient but also environmentally responsible.

Conclusion

Fiberglass food grade equipment represents a significant advancement in the materials used for food processing and storage. Its durability, lightweight nature, non-reactive qualities, ease of cleaning, and versatility make it an appealing choice for businesses aiming to enhance their operational efficiency while ensuring food safety. As the food industry continues to prioritize health standards and environmental responsibility, the demand for fiberglass food grade equipment is likely to grow, paving the way for a safer and more sustainable future in food processing. Whether you are involved in manufacturing, processing, or food service, considering fiberglass as a material choice can lead to valuable benefits and improvements in your operations.

Latest news

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025