-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Feb . 19, 2025 10:11

Back to list

Scrubbers

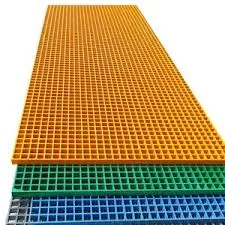

Fiberglass food-grade equipment is emerging as a game-changer in the food processing industry, redefining safety standards while enhancing efficiency. This cutting-edge technology is gaining momentum, thanks to its unique properties and their potential to revolutionize food production environments.

Fiberglass’s versatility is amplified by its customization potential. In food-grade applications, adaptability can enhance productivity. Custom molds allow for making equipment that precisely meets the unique demands of different food processing tasks. This flexibility in design empowers manufacturers to optimize their production lines aspiring to elevated efficiency levels. Furthermore, from an environmental perspective, fiberglass emerges as a sustainable contender. Unlike many materials, fiberglass is non-toxic and can be produced with limited environmental footprint. This aligns seamlessly with the growing regulatory and consumer-driven focus on green manufacturing practices. Testimony to its efficacy can be found in numerous case studies where companies have integrated fiberglass components seamlessly into their existing lines, witnessing significant reductions in maintenance intermittencies and downtimes. These examples underscore fiberglass's authoritative capabilities as a reliable, long-term investment in food safety and production efficiency. As industry experts continue to evaluate the roles of materials in food safety, fiberglass undoubtedly asserts itself as a frontrunner, harmonizing innovative technology with practical application. Specialists in the field recommend further exploration of potential applications within tailored contexts, ensuring businesses maximize returns yielded from fiberglass' adaptable, durable, and safe nature. In conclusion, fiberglass food-grade equipment deserves consideration for its diverse attributes that bolster safety and promote effectiveness. Businesses looking to innovate their food processing methods while upholding stringent health standards will find in fiberglass a robust ally lifting operations into the new age of production.

Fiberglass’s versatility is amplified by its customization potential. In food-grade applications, adaptability can enhance productivity. Custom molds allow for making equipment that precisely meets the unique demands of different food processing tasks. This flexibility in design empowers manufacturers to optimize their production lines aspiring to elevated efficiency levels. Furthermore, from an environmental perspective, fiberglass emerges as a sustainable contender. Unlike many materials, fiberglass is non-toxic and can be produced with limited environmental footprint. This aligns seamlessly with the growing regulatory and consumer-driven focus on green manufacturing practices. Testimony to its efficacy can be found in numerous case studies where companies have integrated fiberglass components seamlessly into their existing lines, witnessing significant reductions in maintenance intermittencies and downtimes. These examples underscore fiberglass's authoritative capabilities as a reliable, long-term investment in food safety and production efficiency. As industry experts continue to evaluate the roles of materials in food safety, fiberglass undoubtedly asserts itself as a frontrunner, harmonizing innovative technology with practical application. Specialists in the field recommend further exploration of potential applications within tailored contexts, ensuring businesses maximize returns yielded from fiberglass' adaptable, durable, and safe nature. In conclusion, fiberglass food-grade equipment deserves consideration for its diverse attributes that bolster safety and promote effectiveness. Businesses looking to innovate their food processing methods while upholding stringent health standards will find in fiberglass a robust ally lifting operations into the new age of production.

Next:

Related Products