-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

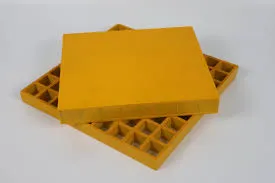

Benefits of Using Fiberglass Grating in Various Industrial Applications

Fiberglass Grating A Versatile Solution for Modern Applications

Fiberglass grating, an innovative material widely used across various industries, represents a robust solution for flooring, walkways, and platforms. It is manufactured from a composite of fiberglass reinforced plastic (FRP), which gives it excellent strength, durability, and corrosion resistance compared to traditional materials like steel and wood. Here, we explore the numerous advantages and applications of fiberglass grating, making it an ideal choice for both industrial and commercial settings.

One of the primary benefits of fiberglass grating is its exceptional strength-to-weight ratio. This unique property allows for easy handling and installation while maintaining structural integrity under heavy loads. The inherent strength of fiberglass ensures that the grating can withstand extreme temperatures, chemicals, and harsh environmental conditions without warping or rusting. As a result, it is a popular choice in environments such as wastewater treatment plants, chemical processing facilities, and marine applications where exposure to corrosive substances is common.

Safety is another significant aspect of fiberglass grating. The surface can be customized with anti-slip textures, providing enhanced traction and reducing the risk of slips and falls, even when wet. This safety feature makes it particularly valuable for use in pedestrian walkways, industrial facilities, and platforms where personnel are frequently moving across surfaces. Additionally, fiberglass grating is non-conductive, making it an excellent choice for electrical applications, adding another layer of safety for workers in various sectors.

fiberglass grating

Another advantage is the lightweight nature of fiberglass grating compared to steel or aluminum. This feature not only simplifies transportation but also reduces labor costs during installation due to its ease of handling. Furthermore, the fiberglass material does not require regular painting or maintenance, resulting in long-term cost savings. Unlike metal gratings that often succumb to rusting or corrosion over time, fiberglass necessitates minimal upkeep, ensuring that structures maintain their integrity and aesthetic appeal throughout their lifespan.

The versatility of fiberglass grating is evident in its applications. It is utilized in a wide range of fields, including construction, food processing, shipbuilding, and oil and gas industries. Customizable in various sizes, colors, and styles, fiberglass grating can suit any project requirement, whether for aesthetic purposes or specific functional needs. Its design can accommodate various light and ventilation requirements, making it ideal for applications where illumination and airflow are critical, such as greenhouse floors or sewage treatment plants.

Moreover, the sustainability aspect of fiberglass grating cannot be overlooked. With an increasing focus on eco-friendly materials, fiberglass grating offers a viable alternative to traditional flooring solutions. Its longevity and resistance to decay contribute to reduced waste generation and fewer replacements over time. Additionally, advancements in manufacturing processes have led to more environmentally friendly practices in producing fiberglass composites.

In conclusion, fiberglass grating is a remarkable product combining strength, safety, and versatility to meet the diverse needs of contemporary industries. With its robust performance under adverse conditions, low-maintenance requirements, and customizable nature, it stands as a testament to modern engineering. As industries continue to evolve, the demand for innovative materials like fiberglass grating will undoubtedly grow, providing sustainable and effective solutions for various applications. Whether for industrial usage or commercial projects, fiberglass grating remains an indispensable resource in promoting safety and efficiency.