-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Feb . 14, 2025 08:39

Back to list

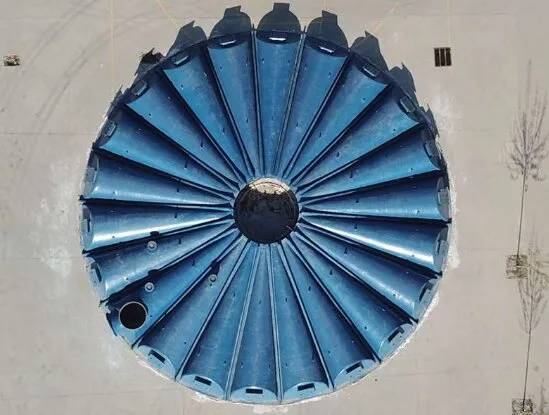

fiberglass grating

Fiberglass grating has become a transformative material in various industries due to its unique blend of durability, versatility, and safety features. As industries such as chemical processing, marine, and sewage treatment continually seek better materials, fiberglass grating stands out as an exemplary choice. This comprehensive exploration draws on extensive expertise, real-world applications, and authoritative insights to highlight the unparalleled benefits and applications of fiberglass grating.

Experts agree that the versatile nature of fiberglass grating opens up a wide array of design possibilities. It can be custom-manufactured to various specifications and colors, catering to specific project needs and aesthetic preferences. This flexibility not only supports functional requirements but also offers architectural appeal, a dual benefit that enhances the value proposition of fiberglass grating for developers and project managers. The benefits of fiberglass grating are not merely theoretical but have been proven across numerous applications. For example, in the marine industry, fiberglass grating is used for deck grates, walkways, and docks, where exposure to the corrosive effects of seawater is a daily challenge. In wastewater treatment facilities, this material proves invaluable in trench covers and platform surfaces, where chemical resistance and non-conductivity are crucial for safety and efficiency. Trust in fiberglass grating is bolstered by endorsements from structural engineers and material scientists who emphasize its performance advantages confirmed through rigorous testing and field use. These expert opinions, coupled with certifications from industry regulatory bodies, further establish fiberglass grating as a material of choice that commands reliability and authority in its application. In conclusion, the strategic incorporation of fiberglass grating in industrial and commercial projects addresses a myriad of durability, safety, and efficiency challenges. It symbolizes a forward-thinking approach that benefits from expert insights and real-world evidence, reinforcing its status as a reliable and authoritative solution. Through this exploration, it is evident that fiberglass grating not only meets but exceeds industry expectations, paving the way for smarter, safer, and more sustainable industrial progress.

Experts agree that the versatile nature of fiberglass grating opens up a wide array of design possibilities. It can be custom-manufactured to various specifications and colors, catering to specific project needs and aesthetic preferences. This flexibility not only supports functional requirements but also offers architectural appeal, a dual benefit that enhances the value proposition of fiberglass grating for developers and project managers. The benefits of fiberglass grating are not merely theoretical but have been proven across numerous applications. For example, in the marine industry, fiberglass grating is used for deck grates, walkways, and docks, where exposure to the corrosive effects of seawater is a daily challenge. In wastewater treatment facilities, this material proves invaluable in trench covers and platform surfaces, where chemical resistance and non-conductivity are crucial for safety and efficiency. Trust in fiberglass grating is bolstered by endorsements from structural engineers and material scientists who emphasize its performance advantages confirmed through rigorous testing and field use. These expert opinions, coupled with certifications from industry regulatory bodies, further establish fiberglass grating as a material of choice that commands reliability and authority in its application. In conclusion, the strategic incorporation of fiberglass grating in industrial and commercial projects addresses a myriad of durability, safety, and efficiency challenges. It symbolizes a forward-thinking approach that benefits from expert insights and real-world evidence, reinforcing its status as a reliable and authoritative solution. Through this exploration, it is evident that fiberglass grating not only meets but exceeds industry expectations, paving the way for smarter, safer, and more sustainable industrial progress.

Next:

Related Products