-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Mar . 06, 2025 16:05

Back to list

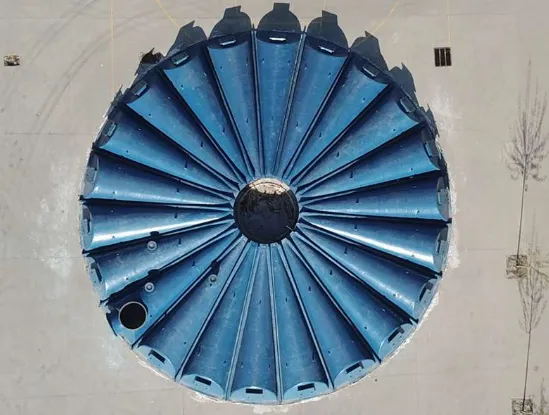

Mandrels and Molds

In the industrial world, efficiency and safety are non-negotiable. Fiberglass grating has emerged as a material of choice, revolutionizing multiple sectors with its remarkable properties. This article delves into the significant advantages of fiberglass grating, drawing upon real-world experiences and expert insights to demonstrate its authority and trustworthiness within the industry.

From an expert perspective, the versatility of fiberglass grating extends beyond its mechanical properties. It is available in a variety of panel sizes, thicknesses, and colors, offering a customizable solution tailored to specific industrial needs. The ability to adapt to unique project requirements without compromising performance showcases its expert-level adaptability in diverse environments. In terms of authoritativeness, fiberglass grating complies with rigorous industry standards and certifications, such as ASTM and OSHA, underscoring its legitimacy and performance credibility. The ongoing research and development efforts in optimizing resin formulations and fiberglass compositions ensure that the material remains at the forefront of industrial innovation. Manufacturers and engineers consistently recognize fiberglass grating as a reliable choice, often benchmarking its quality and performance as industry standards. Real-world applications and case studies further solidify trust in fiberglass grating. In transportation infrastructures like pedestrian bridges and helicopter pads, its lightweight yet robust nature has enabled projects to move forward with reduced environmental footprints and minimal disruption. Feedback from industry leaders who have implemented fiberglass grating underscores its reliability and efficacy. In conclusion, fiberglass grating offers an unparalleled combination of strength, safety, and adaptability, making it a premium choice in various industrial sectors. Its capacity to withstand corrosive environments, minimize risks, and deliver long-term cost efficiency is backed by extensive expertise and positive real-world experiences. As industries evolve, the authoritative presence of fiberglass grating continues to uphold its status as a material synonymous with innovation and dependability, driving future advancements with unwavering trustworthiness.

From an expert perspective, the versatility of fiberglass grating extends beyond its mechanical properties. It is available in a variety of panel sizes, thicknesses, and colors, offering a customizable solution tailored to specific industrial needs. The ability to adapt to unique project requirements without compromising performance showcases its expert-level adaptability in diverse environments. In terms of authoritativeness, fiberglass grating complies with rigorous industry standards and certifications, such as ASTM and OSHA, underscoring its legitimacy and performance credibility. The ongoing research and development efforts in optimizing resin formulations and fiberglass compositions ensure that the material remains at the forefront of industrial innovation. Manufacturers and engineers consistently recognize fiberglass grating as a reliable choice, often benchmarking its quality and performance as industry standards. Real-world applications and case studies further solidify trust in fiberglass grating. In transportation infrastructures like pedestrian bridges and helicopter pads, its lightweight yet robust nature has enabled projects to move forward with reduced environmental footprints and minimal disruption. Feedback from industry leaders who have implemented fiberglass grating underscores its reliability and efficacy. In conclusion, fiberglass grating offers an unparalleled combination of strength, safety, and adaptability, making it a premium choice in various industrial sectors. Its capacity to withstand corrosive environments, minimize risks, and deliver long-term cost efficiency is backed by extensive expertise and positive real-world experiences. As industries evolve, the authoritative presence of fiberglass grating continues to uphold its status as a material synonymous with innovation and dependability, driving future advancements with unwavering trustworthiness.

Next:

Related Products