-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

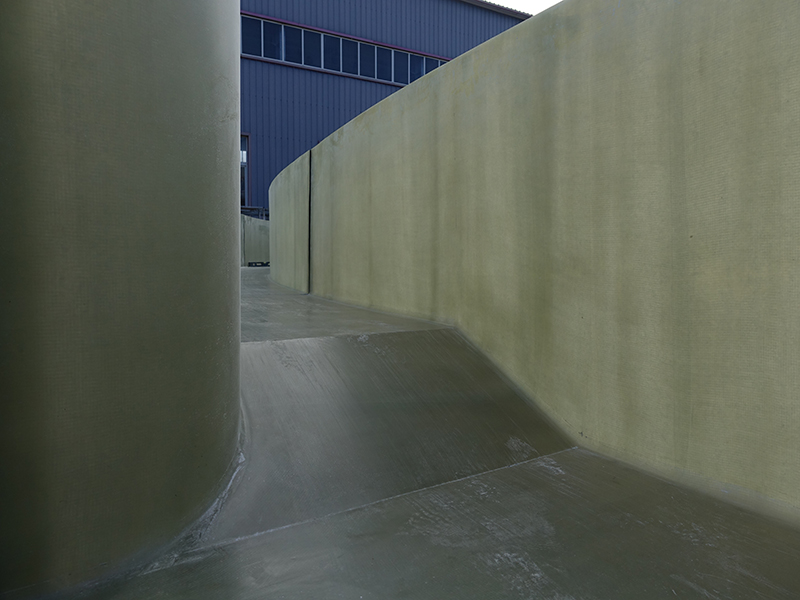

fiberglass insulation tank

The Benefits of Fiberglass Insulation Tanks

In today's world, where energy efficiency and sustainability are at the forefront of environmental discussions, it is essential to explore innovative materials that contribute to these goals. One such material that has gained significant attention in various industries is fiberglass insulation. Among its many applications, fiberglass insulation tanks have recently emerged as a practical solution for energy conservation, particularly in the realm of industrial storage.

What are Fiberglass Insulation Tanks?

Fiberglass insulation tanks are storage units made from fiberglass-reinforced plastic (FRP) that are designed to hold a variety of substances, including liquids, gases, and even solids. These tanks incorporate insulation materials into their structure, allowing them to maintain temperature stability and reduce energy consumption. This makes them particularly advantageous in industries requiring temperature-sensitive materials, such as chemicals, food and beverages, and pharmaceuticals.

Energy Efficiency

One of the primary advantages of fiberglass insulation tanks is their exceptional insulating properties. The fiberglass insulation imbued in the tank walls minimizes heat transfer, keeping contents at the desired temperature for an extended period. This is particularly beneficial for industries where temperature control is crucial. For example, in the food and beverage sector, maintaining the right temperature for ingredients can significantly affect product quality and shelf life. In such cases, fiberglass insulation tanks can drastically reduce energy costs by minimizing the need for additional heating or cooling.

Durability and Corrosion Resistance

Fiberglass is known for its remarkable strength-to-weight ratio and resistance to corrosion, making it an excellent choice for tank construction. Unlike traditional materials, such as steel or concrete, fiberglass does not rust or corrode when exposed to harsh chemicals or environmental conditions. This durability extends the life of the tank and reduces maintenance costs, resulting in a wise long-term investment for businesses.

Moreover, fiberglass insulation tanks are lightweight, making them easier to transport and install compared to their heavier counterparts. This can lead to reduced labor costs and facilitate the erection of larger tanks that might be cumbersome in other materials.

fiberglass insulation tank

Environmental Impact

In an era where many industries are striving to reduce their carbon footprints, fiberglass insulation tanks contribute positively to sustainability efforts. By improving energy efficiency, they help reduce greenhouse gas emissions associated with energy production. Furthermore, the production of fiberglass can be less harmful to the environment when compared to processes involved in producing metal or concrete tanks, which often require extensive mining and energy use.

Additionally, fiberglass insulation tanks can be manufactured to incorporate recycled materials, further promoting environmental responsibility. The ability to choose eco-friendly options in tank construction aligns with the growing demand for sustainability in industrial practices, helping businesses meet regulatory compliance and consumer expectations.

Versatility in Applications

Another significant advantage of fiberglass insulation tanks is their versatility. They can be tailored to specific industry needs and can be designed to meet various sizes, shapes, and storage requirements. Whether for a manufacturing plant, a wastewater treatment facility, or a food processing operation, fiberglass insulation tanks can be customized to suit particular applications, making them a pragmatic choice across diverse sectors.

Safety Features

Fiberglass insulation tanks also offer enhanced safety features. The non-corrosive nature of fiberglass reduces the risk of tank failure due to material degradation, which can pose safety hazards in chemical storage. Moreover, fiberglass is less likely to shatter or break, reducing the risk of leaks or spills. Many modern fiberglass tanks are also designed with secondary containment measures, ensuring that any accidental release of contents is contained, thus protecting the environment and surrounding communities.

Conclusion

In conclusion, fiberglass insulation tanks represent a smart and effective solution for industries looking to improve energy efficiency, reduce costs, and enhance sustainability. Their durability, insulating properties, and versatility make them a strategic option for various applications. As industries move toward greener practices and seek innovative materials to meet their operational needs, fiberglass insulation tanks will undoubtedly play a pivotal role in the future of industrial storage solutions, paving the way for a more energy-efficient and environmentally friendly paradigm.

Latest news

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025