-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Feb . 14, 2025 10:50

Back to list

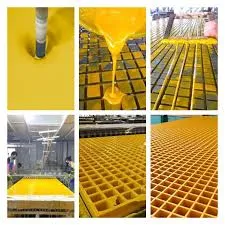

fiberglass insulation tank

Fiberglass insulation tanks have become a cornerstone in the realm of efficient thermal management and storage solutions across various industries. With their unique combination of durability, versatility, and thermal resistance, these tanks are now considered an optimal choice for both commercial and residential applications. This article discusses the numerous advantages of fiberglass insulation tanks and why they are gaining favor over traditional materials.

Safety is another key advantage of fiberglass insulation tanks. Fiberglass does not conduct electricity, minimizing the risk of hazardous sparking—a critical safety feature when storing flammable materials. Furthermore, fiberglass is non-toxic and environmentally friendly, offering a safer alternative for both workers and the surrounding environment. The thermal efficiency of fiberglass insulation tanks contributes directly to energy savings. By minimizing heat loss, these tanks reduce the energy required to maintain the contents at desired temperatures. This reduction in energy usage not only lowers operational costs but also contributes to a lower carbon footprint, aligning with global sustainability initiatives. From a regulatory standpoint, fiberglass insulation tanks meet a variety of industry standards, which underscores their reliability and safety. Manufacturers design these tanks to comply with stringent guidelines specified by organizations such as the American Society of Mechanical Engineers (ASME), the National Sanitation Foundation (NSF), and other governing bodies depending on the application. In conclusion, fiberglass insulation tanks offer a multitude of benefits that make them a superior choice for thermal insulation and storage across various industries. Their combination of corrosion resistance, adaptability, lightweight structure, safety features, and compliance with industry standards ensures that they provide long-term value to any operation. As industries continue to prioritize efficiency and sustainability, the adoption of fiberglass insulation tanks is poised to increase, making them a future-forward choice that underscores contemporary industry needs.

Safety is another key advantage of fiberglass insulation tanks. Fiberglass does not conduct electricity, minimizing the risk of hazardous sparking—a critical safety feature when storing flammable materials. Furthermore, fiberglass is non-toxic and environmentally friendly, offering a safer alternative for both workers and the surrounding environment. The thermal efficiency of fiberglass insulation tanks contributes directly to energy savings. By minimizing heat loss, these tanks reduce the energy required to maintain the contents at desired temperatures. This reduction in energy usage not only lowers operational costs but also contributes to a lower carbon footprint, aligning with global sustainability initiatives. From a regulatory standpoint, fiberglass insulation tanks meet a variety of industry standards, which underscores their reliability and safety. Manufacturers design these tanks to comply with stringent guidelines specified by organizations such as the American Society of Mechanical Engineers (ASME), the National Sanitation Foundation (NSF), and other governing bodies depending on the application. In conclusion, fiberglass insulation tanks offer a multitude of benefits that make them a superior choice for thermal insulation and storage across various industries. Their combination of corrosion resistance, adaptability, lightweight structure, safety features, and compliance with industry standards ensures that they provide long-term value to any operation. As industries continue to prioritize efficiency and sustainability, the adoption of fiberglass insulation tanks is poised to increase, making them a future-forward choice that underscores contemporary industry needs.

Next:

Related Products