-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

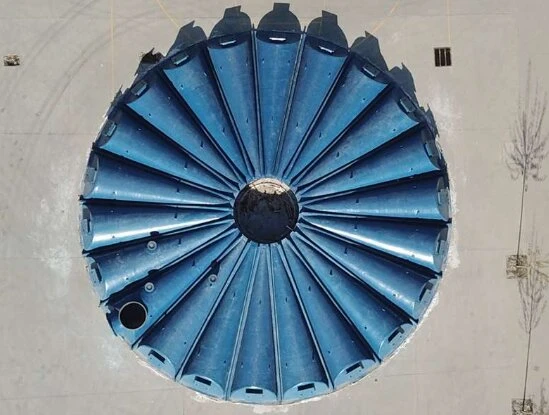

fiberglass launder

The Role of Fiberglass Launders in Modern Industrial Applications

In the contemporary landscape of industrial manufacturing, fiberglass launder systems have emerged as an essential component in various sectors, particularly in the metallurgy and metal casting industries. These specialized channels facilitate the efficient transport of molten metals and other materials, proving indispensable in ensuring safe and effective processes. This article will explore the benefits, applications, and future potential of fiberglass launders.

What is a Fiberglass Launder?

A launder, in its simplest definition, is a channel or trough used to convey liquids, especially molten metals, from one location to another. The construction of these launders from fiberglass reinforced plastic (FRP) provides unique advantages over traditional materials like metal or concrete. Fiberglass is lightweight yet strong, resistant to corrosion, and can be molded into complex shapes, making it a versatile solution for modern industrial needs.

Key Benefits of Fiberglass Launders

1. Corrosion Resistance One of the standout features of fiberglass is its resistance to chemical and environmental degradation. In industries dealing with corrosive materials, fiberglass launders significantly reduce maintenance costs and prolong the lifespan of the equipment. Unlike metal launders, which can rust or corrode, fiberglass remains intact even under harsh conditions, ensuring that operations run smoothly without unexpected interruptions.

2. Lightweight Properties Fiberglass launders are considerably lighter than their metal counterparts. This lightweight nature simplifies installation and reduces the structural support required, allowing for more flexible designs. Factories can save on labor costs and accelerate the installation process, contributing to overall operational efficiency.

3. Thermal Insulation Fiberglass has natural thermal insulating properties, which is crucial when transporting high-temperature materials like molten metal. This insulation helps maintain the temperature of the molten metal, reducing heat loss and ensuring that the material arrives at its intended destination in optimal condition. Improved thermal management can lead to better quality outputs and less waste.

4. Customizability The manufacturing process for fiberglass allows for great versatility in design. Fiberglass launders can be custom-fabricated to fit specific dimensions and needs of a facility. This adaptability means that businesses can optimize their systems for maximum efficiency and space utilization, which is especially important in facilities with complex layouts.

fiberglass launder

Applications in Industry

Fiberglass launders are primarily used in metal casting and foundry operations, where they play a crucial role in the transfer of molten metal from furnaces to molds or cooling areas. Their properties make them ideal for environments where high temperatures and corrosive materials are commonplace. Additionally, fiberglass launders are increasingly being employed in wastewater management systems, where they transport liquid waste and chemicals in treatment facilities.

Industries such as aerospace, automotive, and construction also benefit from fiberglass launders. In aerospace engineering, for instance, lightweight fiberglass channels are used to handle the transfer of specialized materials and fluids with utmost precision and safety.

Future Prospects

As industries continue to evolve, the future of fiberglass launders looks promising. Innovations in material science may lead to even more advanced fiberglass composites that offer improved properties, such as enhanced thermal resistance or greater structural strength. Additionally, as global standards for environmental protection become more stringent, businesses must find ways to reduce waste and improve efficiencies. Fiberglass launders will likely play an integral role in achieving these sustainability goals.

Emerging technologies such as automation and smart manufacturing also hold the potential to enhance the functionality of fiberglass launders. Integrating sensors and monitoring systems into launder designs could provide real-time data on fluid flow and temperature, allowing for optimized operations and reduced downtime.

Conclusion

In conclusion, fiberglass launders represent a significant advancement in industrial transportation systems, particularly in the metalworking and wastewater sectors. Their unique properties facilitate safe and efficient transport of materials essential for production processes. As industries face increasing demands for efficiency and sustainability, the role of fiberglass launders is set to expand, proving that innovation in material engineering can lead to remarkable improvements in manufacturing practices. As we look to the future, it's clear that these systems will remain a vital component in the quest for operational excellence.

Latest news

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025