-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

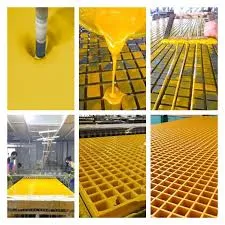

Innovative Solutions for Efficient Water Management Using Fiberglass Launders

The Benefits of Fiberglass Launder Systems in Water Treatment

In the modern landscape of wastewater treatment, efficiency and durability are paramount. One component that has gained significant attention is the fiberglass launder system. These systems, often used in conjunction with sedimentation tanks and clarifiers, provide significant advantages over traditional materials such as metal and concrete. This article explores the benefits, applications, and considerations surrounding fiberglass launder systems.

What is a Fiberglass Launder?

Fiberglass launders are long, trough-like structures made from fiberglass-reinforced plastic (FRP). They are specifically designed to transport liquid, often during the sedimentation process in water and wastewater treatment facilities. The primary function of these launders is to collect and convey wastewater surface flows in an efficient and effective manner, ensuring that the treatment process operates smoothly.

Advantages of Fiberglass Launder Systems

1. Corrosion Resistance One of the standout features of fiberglass launder systems is their exceptional resistance to corrosion. Unlike metal systems, which can deteriorate under harsh chemical conditions, fiberglass maintains its integrity and functionality, even in aggressive environments. This longevity reduces maintenance costs and extends the life of the system.

2. Lightweight and Easy to Install Fiberglass is significantly lighter than traditional materials like concrete or steel. This attribute not only simplifies transportation but also makes installation quicker and less labor-intensive. The ease of installation translates to reduced labor costs and shorter downtime during replacement or upgrades.

3. Smooth Surfaces The smooth interior surfaces of fiberglass launders help reduce the frictional resistance encountered by moving liquids, thereby improving flow rates and reducing the likelihood of clogs. Additionally, the surface properties minimize the buildup of sediment and biofilm, which are common issues in wastewater treatment systems.

fiberglass launder

4. Thermal Stability Fiberglass does not expand or contract significantly with temperature changes compared to metals and concrete. This stability is crucial in maintaining the structural integrity of the launder system and ensuring consistent performance under varying environmental conditions.

5. Customizable Design Fiberglass can be molded into various shapes and sizes, allowing for tailored solutions that meet specific operational requirements. This adaptability can accommodate different treatment processes and site configurations, making fiberglass launders versatile options for any treatment facility.

6. Cost-Effective While the initial investment in fiberglass systems may be higher than traditional materials, the long-term savings due to reduced maintenance, lower replacement costs, and efficient operation often outweigh the upfront expenses. Furthermore, the durability of fiberglass translates to fewer replacements over time.

Applications in Water Treatment

Fiberglass launder systems are widely used in various water treatment processes, including

- Sedimentation Tanks They are essential components in circular and rectangular sedimentation tanks, ensuring that clarified water is efficiently collected and transported. - Dewatering Operations In sludge dewatering, fiberglass launders play a crucial role in managing the flow of dewatered materials. - Cooling Water Systems Fiberglass is ideal for industries dealing with cooling water systems due to its resistance to chemical attacks from various water treatments.

Conclusion

As industries continue to strive for greater efficiency and more effective waste management solutions, fiberglass launder systems emerge as a prudent choice. Their inherent advantages of corrosion resistance, lightweight construction, customizable design, and cost-effectiveness make them indispensable in modern wastewater treatment facilities. By investing in fiberglass systems, operators not only enhance their treatment operations but also contribute to a more sustainable approach to managing water resources. As technology evolves, the adoption and development of fiberglass solutions are likely to keep pace, promising even greater innovations in the water treatment sector.

Latest news

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025