-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

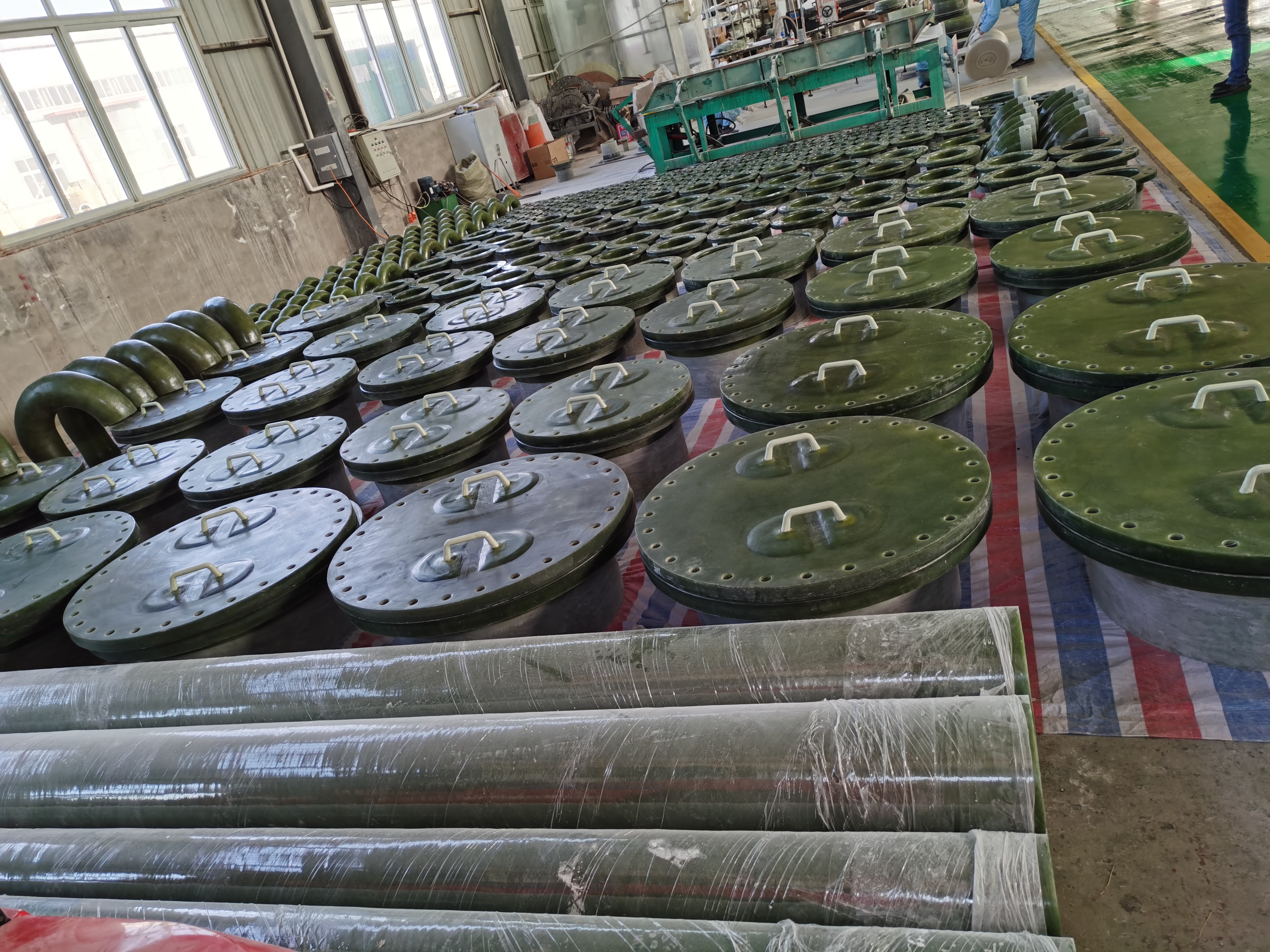

fiberglass launder

A Comprehensive Guide to Fiberglass Launders Benefits and Applications

Fiberglass launders are specialized channels used in various industrial and commercial applications, primarily for the transportation and distribution of liquids, especially in water treatment and chemical processing. These structures are made from fiberglass-reinforced plastics, providing a lightweight, durable, and corrosion-resistant alternative to traditional materials like metal or concrete. The growing popularity of fiberglass launders can be attributed to their numerous benefits and versatility across different sectors.

One of the key advantages of fiberglass launders is their resistance to corrosion and chemical degradation. In environments where aggressive chemicals and harsh weather conditions are prevalent, traditional materials often succumb to corrosion, leading to costly repairs and replacements. Fiberglass, on the other hand, can withstand a wide range of chemical exposures, making it ideal for wastewater treatment plants, chemical processing facilities, and industrial applications.

Another significant benefit of fiberglass launders is their lightweight nature. Compared to metal and concrete, fiberglass is easier to transport and install, reducing overall labor costs and installation time. This lightweight property also means that fiberglass launders can be designed in various shapes and configurations, allowing for more flexibility in system design and layout. Whether for a small-scale facility or a large industrial plant, fiberglass launders can be tailored to meet specific needs and space constraints.

fiberglass launder

In addition to their practical advantages, fiberglass launders also offer excellent hydraulic performance. The smooth inner surfaces of fiberglass promote efficient flow, reducing turbulence and ensuring even distribution of liquids. This characteristic is especially important in processes requiring precise flow management, such as in water treatment, where consistent flow rates are crucial for effective treatment results.

Maintenance is another area where fiberglass launders excel. Their non-porous surface does not harbor bacteria or algae, which are common problems in concrete and metallic systems. This quality not only ensures cleaner operations but also minimizes the need for frequent cleaning, further reducing operational costs.

Furthermore, the production of fiberglass is increasingly being aligned with sustainable practices. Many manufacturers are now incorporating recycled materials into their fiberglass formulation, and the manufacturing process itself can be more environmentally friendly compared to traditional materials. This aligns with the growing trend of sustainability in industry, making fiberglass launders a responsible choice for forward-thinking companies.

In conclusion, fiberglass launders represent a modern, efficient, and sustainable solution for liquid transportation in various industries. Their resistance to corrosion, lightweight nature, superior hydraulic performance, low maintenance requirements, and alignment with sustainability initiatives make them an appealing option for engineers and facility managers. As industries continue to evolve, fiberglass launders will likely play an increasingly important role in innovative fluid handling systems.

Latest news

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025