-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

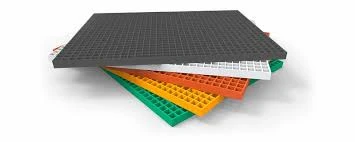

fiberglass pipe fittings

Understanding Fiberglass Pipe Fittings Advantages and Applications

Fiberglass pipe fittings have emerged as a prominent choice in various industries due to their unique properties and advantages. Made from a composite material of glass fibers and resin, these fittings are lightweight, durable, and resistant to a range of environmental conditions. This article explores the benefits of fiberglass pipe fittings, their applications, and why they are becoming a preferred option for many applications.

Advantages of Fiberglass Pipe Fittings

1. Corrosion Resistance One of the most significant advantages of fiberglass pipe fittings is their resistance to corrosion. Unlike traditional metal fittings that can rust or degrade over time due to exposure to chemicals or moisture, fiberglass does not corrode. This makes them an ideal choice for industries dealing with aggressive chemicals, ensuring longevity and reliability of the piping system.

2. Lightweight Fiberglass fittings are considerably lighter than metal alternatives. This characteristic not only simplifies transportation and installation but also reduces the structural load on supporting systems. In applications where weight is a critical factor, such as elevated piping systems, the lightweight nature of fiberglass fittings can lead to significant cost savings and ease of installation.

3. Thermal Insulation Fiberglass fittings have excellent thermal insulation properties. This characteristic helps to maintain the temperature of the transported fluids and reduces energy costs associated with heating or cooling systems. Insulating properties also help to minimize condensation, which can lead to further corrosive damage in other materials.

4. Strength and Durability While being lightweight, fiberglass is exceptionally strong. It has high tensile strength and can withstand considerable pressure without deforming. Fiberglass fittings are resilient to impact and can perform under severe environmental conditions, including high temperature and pressure, making them suitable for a wide range of applications.

5. Low Maintenance Fiberglass pipe fittings require significantly less maintenance compared to traditional materials. Their resistance to corrosion and chemical reactions means fewer repairs and replacements over time, translating to cost savings for businesses.

6. Versatility Fiberglass fittings come in various types and sizes, making them suitable for multiple applications across different industries. They can be molded into complex shapes to meet specific engineering requirements, allowing for customization in various systems.

fiberglass pipe fittings

Applications of Fiberglass Pipe Fittings

Fiberglass pipe fittings are utilized in numerous industries, each benefiting from their unique properties. Some common applications include

- Chemical Processing In chemical plants where hazardous substances are transported, fiberglass fittings provide the necessary corrosion resistance and ensure safe handling of aggressive chemicals.

- Water and Wastewater Treatment Fiberglass fittings are widely used in water treatment facilities. Their resistance to corrosion, lightweight design, and durability make them an excellent choice for both above-ground and underground piping systems.

- Oil and Gas The oil and gas industry often utilizes fiberglass fittings due to their ability to withstand extreme conditions, including high pressures and chemical exposure. They play an essential role in transportation and distribution systems.

- Marine Applications In marine environments, where saltwater can quickly degrade traditional materials, fiberglass’s corrosion resistance is critical. These fittings are used in boatbuilding, dock systems, and other coastal installations.

- Mining Operations Fiberglass fittings are employed in mining for transporting slurry and other abrasive materials due to their strength and durability.

Conclusion

Fiberglass pipe fittings represent a remarkable advancement in piping technology. With their combination of corrosion resistance, lightweight design, strength, and versatility, they are a preferred choice across various industries. As businesses continue to seek durable and low-maintenance solutions, the demand for fiberglass fittings is expected to rise, making them a cornerstone in modern piping systems. Whether in chemical processing, water treatment, or marine applications, their unique properties ensure that they remain a reliable option for the future.