-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

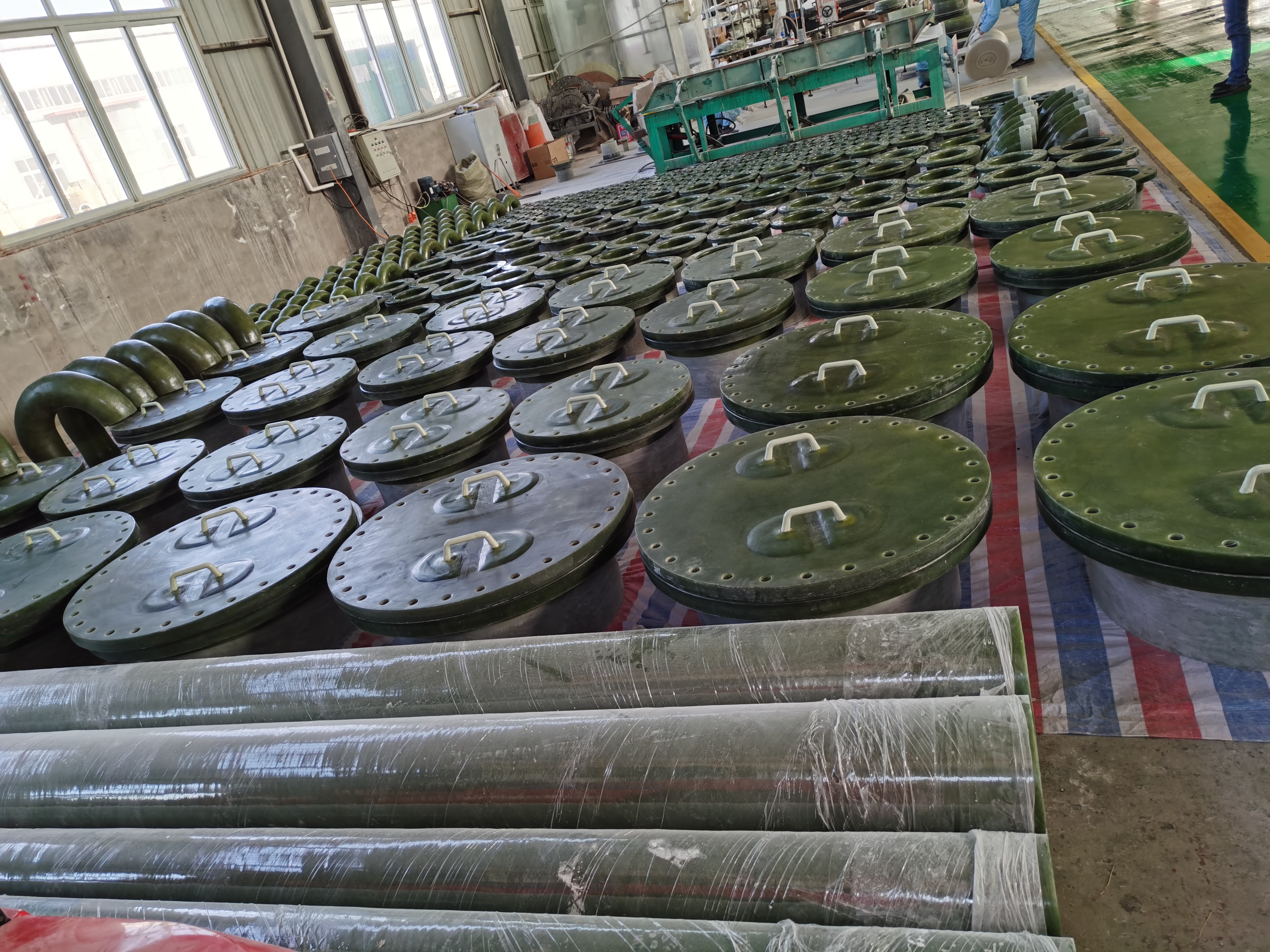

Applications and Benefits of Fiberglass Pipe Flanges in Various Industries

Understanding Fiberglass Pipe Flanges A Comprehensive Overview

Fiberglass pipe flanges are essential components in various industries, where the reliability and durability of piping systems are crucial. Made from a composite material consisting of glass fibers embedded in a resin matrix, these flanges offer numerous advantages compared to traditional metal flanges. This article aims to explore the characteristics, benefits, and applications of fiberglass pipe flanges, providing valuable insights for engineers, designers, and maintenance professionals.

Characteristics of Fiberglass Pipe Flanges

Fiberglass pipe flanges stand out due to their unique composition. The use of glass fibers significantly enhances the strength-to-weight ratio, making them lightweight yet robust. The resin provides excellent chemical resistance, allowing these flanges to be used in harsh environments without corroding or degrading. This feature is particularly advantageous in industries such as chemical processing, wastewater treatment, and water distribution, where exposure to corrosive substances is common.

Additionally, fiberglass pipe flanges exhibit excellent temperature resistance, making them suitable for both high and low-temperature applications. Their ability to withstand thermal expansion and contraction without compromising structural integrity is another critical advantage. This property not only extends the lifespan of the flanges but also reduces maintenance costs associated with replacements or repairs.

Benefits of Using Fiberglass Pipe Flanges

1. Corrosion Resistance One of the primary benefits of fiberglass flanges is their resistance to corrosion. Unlike metal flanges, which can rust or corrode in the presence of moisture or chemicals, fiberglass maintains its integrity over time, leading to improved reliability and reduced downtime in operations.

2. Lightweight The lightweight nature of fiberglass flanges simplifies transportation and installation. This characteristic allows for easier handling, which can significantly decrease labor costs and time during installation, especially in large-scale projects.

3. Cost-Effectiveness While the initial cost of fiberglass flanges may be higher than that of metal flanges, their durability often leads to lower overall costs. The absence of corrosion and the longer lifespan typically result in fewer replacements and maintenance needs, translating to savings in the long run.

4. Thermal Insulation Fiberglass has inherent insulating properties, reducing heat transfer between fluids and the surrounding environment. This is particularly beneficial in systems where temperature regulation is critical, helping maintain process efficiency and the integrity of the materials being transported.

fiberglass pipe flanges

5. Versatility Available in various sizes and designs, fiberglass flanges can be customized to meet specific project requirements. They can also be combined with different types of piping systems, enhancing their applicability across a wide range of industries.

Applications of Fiberglass Pipe Flanges

Fiberglass pipe flanges are utilized in diverse applications, reflecting their versatility and effectiveness

. Some common industries that employ these components include- Chemical Processing In plants where aggressive chemicals are handled, fiberglass flanges provide a safe and durable solution, reducing the risk of leaks and failures.

- Water and Wastewater Treatment The resistance to corrosion and ability to withstand varying temperatures make fiberglass an ideal choice for pipe systems used in treating water and sewage.

- Oil and Gas The lightweight and sturdy nature of fiberglass flanges contributes to the efficiency of onshore and offshore applications where weight reduction is critical.

- Marine Applications The ability to withstand harsh marine environments makes fiberglass flanges suitable for use in vessels and marine infrastructure, ensuring longevity and performance.

- HVAC Systems In heating, ventilation, and air conditioning systems, fiberglass flanges are utilized for their thermal insulation properties, contributing to energy efficiency.

Conclusion

Fiberglass pipe flanges offer a robust and reliable solution for various piping needs across many industries. With their impressive attributes, such as corrosion resistance, lightweight nature, and versatility, they have established themselves as a practical choice for engineers and designers. As industries continually seek materials that enhance performance while reducing costs, fiberglass pipe flanges will likely play an increasingly prominent role in the development of safe, durable, and cost-efficient piping systems. Understanding their characteristics and applications can significantly aid in making informed decisions for future projects.

Latest news

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025