-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

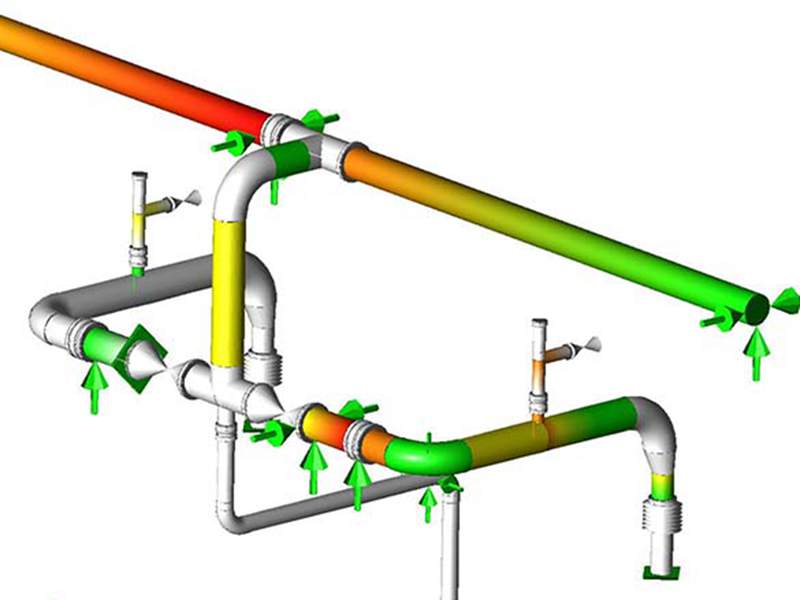

fiberglass pipes and fittings for ship building

The Advantages of Fiberglass Pipes and Fittings in Shipbuilding

In the maritime industry, the integrity and durability of materials used in the construction of ships are paramount. Fiberglass pipes and fittings have emerged as a superior choice for shipbuilding, owing to their numerous advantages over traditional materials such as metal and plastic. This article explores the key benefits of utilizing fiberglass pipes and fittings in shipbuilding.

Lightweight Yet Strong

One of the most significant advantages of fiberglass pipes and fittings is their lightweight nature. Fiberglass, a composite material made from glass fibers and resin, is significantly lighter than metals like steel or aluminum. This reduction in weight contributes to overall fuel efficiency and can enhance vessel performance on the water. Despite their lightweight, fiberglass components maintain exceptional strength and structural integrity, allowing them to withstand the harsh marine environment without compromising reliability.

Corrosion Resistance

Ships are often exposed to harsh conditions, including saltwater, humidity, and varying temperatures. Traditional metallic pipes are susceptible to rust and corrosion under these conditions, resulting in costly maintenance and repairs over the ship's lifespan. Conversely, fiberglass pipes and fittings exhibit superior resistance to corrosion and chemical degradation, ensuring longevity and reducing the overall maintenance costs associated with ship operations.

Easier Installation and Maintenance

The installation of fiberglass pipes is relatively straightforward due to their lightweight nature and flexibility. This ease of handling leads to reduced labor costs and shorter installation timeframes. Additionally, fiberglass pipes do not require special tools for cutting and joining, further streamlining the installation process. Moreover, maintenance is minimal; fiberglass requires less frequent inspection and replacement than traditional systems. This reliability is essential for maintaining operational efficiency and minimizing downtime.

fiberglass pipes and fittings for ship building

Thermal Insulation Properties

Another noteworthy property of fiberglass is its excellent thermal insulation capabilities. Fiberglass pipes can effectively reduce heat transfer, which is particularly beneficial in systems involving hot fluids. This property not only enhances energy efficiency but also helps maintain temperature-sensitive cargo, making fiberglass an optimal choice for various shipboard applications.

Environmental Sustainability

As the industry moves toward more sustainable practices, the use of fiberglass materials aligns with these goals. Fiberglass pipes are often manufactured using eco-friendly processes, and their durability contributes to reduced waste over time. Furthermore, fiberglass can be recycled at the end of its life cycle, thereby minimizing the environmental impact associated with shipbuilding.

Increased Safety

Safety is a critical consideration in shipbuilding. Fiberglass pipes and fittings are non-conductive and do not create sparks, reducing the risk of ignition in flammable environments. Their excellent resistance to extreme temperatures also enhances safety measures on board, making fiberglass a preferred material in the construction of marine systems.

Conclusion

Fiberglass pipes and fittings represent a significant advancement in shipbuilding materials, offering a range of benefits that enhance performance, safety, and longevity. With their lightweight, corrosion resistance, thermal insulation properties, and sustainability, fiberglass components are set to become an integral part of future naval engineering. As the maritime industry continues to evolve, the adoption of such innovative materials will play a crucial role in shaping the ships of tomorrow.