-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

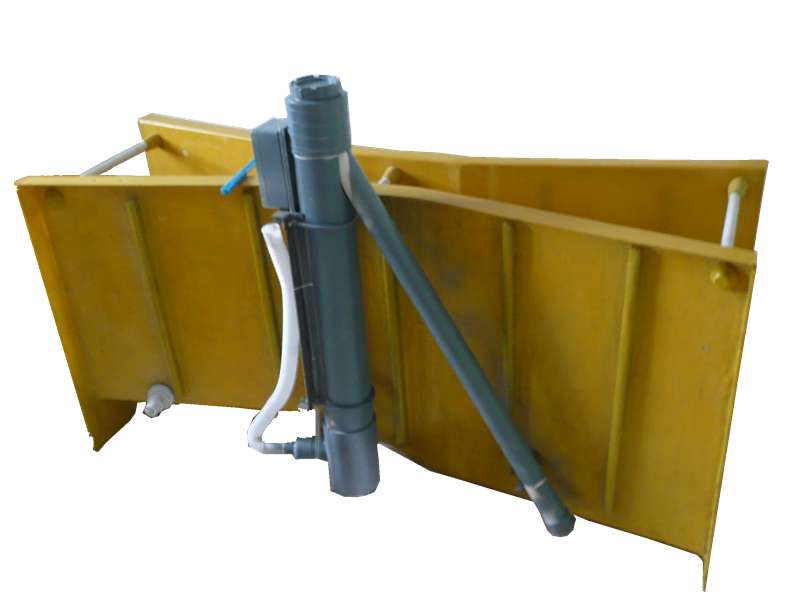

fiberglass pipes and fittings for ship building

Fiberglass Pipes and Fittings for Shipbuilding

In the maritime industry, the choice of materials is critical to ensuring the durability, safety, and efficiency of vessels. One of the most innovative materials that has garnered significant attention in recent years is fiberglass, specifically fiberglass pipes and fittings. These components are increasingly being utilized in various aspects of shipbuilding, offering a range of advantages over traditional materials such as steel or plastic.

Fiberglass, or glass-reinforced plastic (GRP), is created by combining glass fibers with resin, resulting in a composite that possesses unique mechanical properties. When it comes to shipbuilding, fiberglass pipes are particularly advantageous due to their lightweight nature. This reduction in weight is crucial, as it contributes to overall fuel efficiency and reduces the vessel's carbon footprint. Furthermore, lighter materials can enhance the vessel's speed and maneuverability, making them an attractive choice for modern ship designs.

Another significant advantage of fiberglass pipes and fittings is their corrosion resistance. Traditional metals, while strong, are susceptible to rust and other forms of corrosion when exposed to seawater and harsh marine environments. In contrast, fiberglass exhibits excellent resistance to such environmental factors, which translates to lower maintenance costs and longer service life. This property makes fiberglass an ideal choice for applications involving water transport, such as piping systems for ballast water management, fresh water supply, and waste management.

fiberglass pipes and fittings for ship building

Moreover, the chemical resistance of fiberglass allows these pipes and fittings to be used in various applications beyond simple fluid transport. They can effectively handle aggressive chemicals encountered in marine environments, making them suitable for cargo tanks, bilge systems, and more. Additionally, the smooth interior surface of fiberglass pipes minimizes friction losses and helps maintain the efficiency of fluid transport.

The installation of fiberglass pipes is also more straightforward compared to their metal counterparts. The lightweight nature of fiberglass allows for easier handling and reduces installation costs. Adhesive joints used in fiberglass fittings can provide a leak-proof seal, further contributing to the reliability of the systems they are part of.

In conclusion, the use of fiberglass pipes and fittings in shipbuilding represents a significant advancement in materials technology. Their lightweight, corrosion and chemical resistance, as well as ease of installation, make them an excellent choice for a variety of applications across the maritime sector. As the industry moves toward more sustainable practices, the adoption of fiberglass materials may continue to grow, ensuring safer and more efficient vessels for the future.