-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

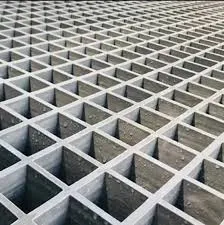

fiberglass pipes and fittings for ship building

Fiberglass Pipes and Fittings for Shipbuilding A Comprehensive Overview

In the maritime industry, the construction of vessels requires materials that can withstand harsh marine environments while offering durability, lightweight characteristics, and resistance to corrosion. Fiberglass pipes and fittings have emerged as a preferred choice for shipbuilding, revolutionizing the way vessels are designed and constructed.

Advantages of Fiberglass Pipes and Fittings

1. Corrosion Resistance One of the primary advantages of fiberglass-reinforced plastic (FRP) pipes and fittings is their exceptional resistance to corrosion. Unlike traditional materials such as steel or aluminum, fiberglass does not corrode when exposed to seawater, chemicals, or other corrosive environments. This property makes it particularly suited for shipbuilding, where pipes are often subjected to harsh marine conditions.

2. Lightweight Fiberglass components are significantly lighter than their metal counterparts. This weight reduction translates to lower overall weight for the ship, which can enhance fuel efficiency and increase cargo capacity. The lightweight nature of fiberglass also simplifies installation and reduces labor costs during the construction process.

3. High Strength-to-Weight Ratio Fiberglass pipes and fittings provide a remarkable strength-to-weight ratio. This means that they can endure high pressures and loads without being overly heavy, making them ideal for various applications on ships, including hydraulic systems, ballast systems, and wastewater management.

4. Flexibility in Design Another advantage of using fiberglass is its versatility in design. Manufacturers can produce a wide range of shapes and sizes, allowing for customized pipes and fittings tailored to specific marine applications. This flexibility also enables designers to create complex layouts that optimize space utilization within the vessel.

5. Thermal Insulation Fiberglass has inherent thermal insulating properties, which can be beneficial for regulating internal temperatures within various compartments of a ship. This insulation helps to minimize heat transfer, contributing to energy efficiency, particularly for systems that require temperature control.

Applications in Shipbuilding

fiberglass pipes and fittings for ship building

Fiberglass pipes and fittings find numerous applications in the shipbuilding industry. They are commonly used in

- Ballast Systems Ensuring the stability of a ship is crucial. Fiberglass pipes are employed in ballast systems that manage water intake and discharge, helping to maintain the vessel's balance and sea-worthiness.

- Wastewater Systems The management of wastewater is essential for all ships. Fiberglass is preferred for sewage and gray water systems due to its resistance to corrosion and ease of maintenance.

- Firefighting Systems Fire safety systems on vessels must operate efficiently under extreme conditions. Fiberglass pipes can be utilized in fire suppression systems, offering reliability and longevity.

- Cooling Systems A ship's engine and machinery require effective cooling. Fiberglass pipes are often used in cooling water systems due to their resistance to temperature extremes and chemical interaction with seawater.

Sustainability Considerations

In recent years, the shipbuilding industry has placed greater emphasis on sustainability. Fiberglass pipes and fittings are manufactured with a lower environmental impact compared to traditional materials. They can be designed to be recyclable at the end of their life cycle, contributing to eco-friendly practices in ship construction. The lightweight nature of fiberglass further supports fuel efficiency, leading to reduced greenhouse gas emissions during the operational lifespan of the vessel.

Conclusion

Fiberglass pipes and fittings have established themselves as a vital component in modern shipbuilding. With their superior corrosion resistance, lightweight nature, and ability to withstand harsh marine environments, they present numerous advantages over traditional materials. As the maritime industry continues to evolve towards more sustainable and efficient practices, the role of fiberglass in shipbuilding is likely to expand, paving the way for innovative vessel designs that meet the demands of today’s and tomorrow's maritime challenges.