-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

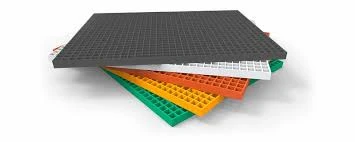

High-Temperature Fiberglass Solutions for Industrial Applications and Enhanced Performance

The Role of Fiberglass Products in High-Temperature Applications

Fiberglass products have gained significant traction in various industries due to their remarkable characteristics and versatility. Among the numerous applications of fiberglass, its usage in high-temperature environments stands out, showcasing its unique properties that make it suitable for demanding conditions. As industries such as aerospace, automotive, and energy production continue to escalate their operational temperatures, the role of fiberglass in maintaining efficiency and safety cannot be overstated.

Understanding Fiberglass

Fiberglass, or glass-reinforced plastic (GRP), is composed of a plastic matrix reinforced with fine glass fibers. The incorporation of glass fibers not only enhances the tensile strength and durability of the material but also significantly improves its thermal resistance. Fiberglass can endure temperatures ranging from 200°C to over 1000°C, depending on the type of resin and fiberglass used. This capability to withstand high temperatures makes it an ideal choice for components that face extreme thermal conditions.

Applications in High-Temperature Scenarios

1. Aerospace Industry In the aerospace sector, fiberglass materials are pivotal. They are utilized in the construction of parts that must withstand significant heat during flight, including engine components and thermal protection systems. The lightweight nature of fiberglass contributes to overall fuel efficiency in aircraft, while its ability to withstand high temperatures ensures reliability and safety.

2. Automotive Industry Similarly, in the automotive industry, fiberglass is frequently used in the manufacture of heat shields, exhaust systems, and components that operate near high-temperature areas of the engine. The integration of fiberglass products leads to enhanced performance as they help insulate sensitive electronic components from heat, ensuring a longer life and improved functionality.

fiberglass products for high temperature

3. Energy Production In energy production, especially in power plants where high thermal efficiency is paramount, fiberglass products are utilized in insulations and as part of cooling systems. Their low thermal conductivity effectively reduces heat loss, promoting energy conservation and efficiency.

4. Industrial Applications Other industrial applications include the use of fiberglass in furnaces, kilns, and other environments where exposure to extreme temperatures is common. The strength and thermal stability of fiberglass products help support structures and components under intense heat, reducing the risk of failure and ensuring operational safety.

Advantages of Fiberglass Over Other Materials

When evaluated against traditional materials such as metals or ceramics, fiberglass presents several advantages. Firstly, it is significantly lighter than metals, leading to easier handling and lower transportation costs. Moreover, fiberglass does not corrode or oxidize under high-temperature conditions, which is often a drawback of metal components. Its resistance to chemical degradation also extends its lifecycle in harsh environments.

The production of fiberglass components can be more cost-effective as well. The ability to mold fiberglass into complex shapes reduces the need for additional machining processes, thus streamlining production and lowering labor costs.

Conclusion

In conclusion, fiberglass products have proven to be indispensable in high-temperature applications across various sectors. Their unique combination of heat resistance, lightweight properties, and durability make them a premier choice for industries that operate under extreme conditions. As advancements in fiberglass technology continue to evolve, we can expect even broader applications and enhanced performance, reinforcing fiberglass's position as a vital material in the modern industrial landscape. Whether in aircraft soaring through the skies, cars navigating challenging terrains, or power plants generating energy, fiberglass is a key player in ensuring success and safety amidst heat and pressure.