-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

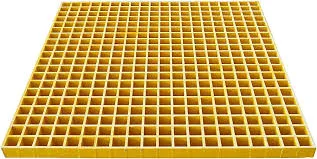

fiberglass products for high temperature

Fiberglass Products for High Temperature Applications

Fiberglass, a material known for its versatility and strength, has gained significant traction in industries that require high-temperature resistance. This feature, coupled with its lightweight properties and excellent insulation capabilities, makes fiberglass an ideal choice for a variety of applications that operate under extreme conditions.

One of the primary reasons fiberglass is favored in high-temperature settings is its ability to withstand significant heat without losing structural integrity. Standard fiberglass can typically endure temperatures of up to 450°F (232°C), while specialized types can handle temperatures exceeding 1000°F (538°C). This property is crucial in industries such as aerospace, automotive, and manufacturing, where components are often exposed to intense heat.

In the aerospace sector, fiberglass products are used in the construction of parts that must withstand extreme thermal environments. For example, fiberglass composites are utilized in thermal protection systems of aircraft, ensuring safety and performance in high-speed flights. The lightweight nature of fiberglass also contributes to fuel efficiency, making it an advantageous option in aircraft design.

Similarly, in the automotive industry, fiberglass is used in high-temperature applications such as engine components and insulation materials. Parts like spark plug wires and muffler hangers benefit from fiberglass's heat resistance, providing durability and longevity in harsh conditions. The ability of fiberglass to maintain its properties under stress makes it an essential material in modern automotive manufacturing.

fiberglass products for high temperature

Manufacturers producing fiberglass products for high-temperature applications often employ special resin systems and processing techniques to enhance the material's thermal stability. Epoxy and silicone resins are common choices, as they provide additional resistance to heat while offering excellent adhesion and compatibility with fiberglass fibers.

In addition to aerospace and automotive applications, fiberglass is prominent in industrial settings. Insulation materials made from fiberglass are used in high-temperature facilities, such as power plants and refineries, to reduce heat loss and protect personnel from heat exposure. These insulated products help maintain efficient operation while ensuring worker safety.

The application of fiberglass in high-temperature contexts extends beyond traditional uses; it is also being explored in emerging technologies. For instance, as industries seek more efficient and sustainable solutions, innovations involving fiberglass in the realm of renewable energy production—such as wind turbine blades—are becoming increasingly essential.

In conclusion, fiberglass products designed for high-temperature applications play a pivotal role across various industries. Their exceptional thermal resistance, lightweight nature, and durability make them invaluable in ensuring safety and efficiency in environments that demand resilience to extreme heat. As technology continues to advance, the potential applications for high-temperature fiberglass products are likely to expand, paving the way for enhanced performance and innovation in the future.

Latest news

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025