-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

High-Temperature Applications of Fiberglass Products for Enhanced Performance and Durability

Fiberglass Products for High Temperature Applications

In today's industrial landscape, the demand for materials that can withstand extreme conditions is steadily increasing. Industries such as aerospace, automotive, and power generation require components that not only endure high temperatures but also perform reliably under stress. One such material that has been extensively utilized for high-temperature applications is fiberglass. Known for its remarkable properties, fiberglass products have established a significant foothold in various sectors due to their ability to maintain structural integrity and performance even in harsh environments.

What is Fiberglass?

Fiberglass is a composite material made from fine glass fibers combined with a resin matrix. The primary reinforcement material, glass fibers offer exceptional tensile strength, while the resin provides bonding and protection against environmental factors. The versatility of fiberglass is attributed to its ability to be engineered into various forms, including sheets, rods, tubes, and intricate shapes.

High-Temperature Resistance

One of the standout features of fiberglass products is their high-temperature resistance. Standard fiberglass can withstand temperatures up to about 130°C (266°F) without any significant degradation. However, specialized formulations of fiberglass, such as those treated with high-performance resins or containing silica, can tolerate temperatures exceeding 300°C (572°F). This makes fiberglass a viable option for industries that operate in extreme thermal environments.

Applications in Industry

1. Aerospace Industry In the aerospace sector, fiberglass composites are used in the manufacturing of components like fairings, wing structures, and interior linings. The material's high strength-to-weight ratio is a key advantage, as it helps to reduce overall aircraft weight while maintaining safety and performance under high-temperature conditions during flight.

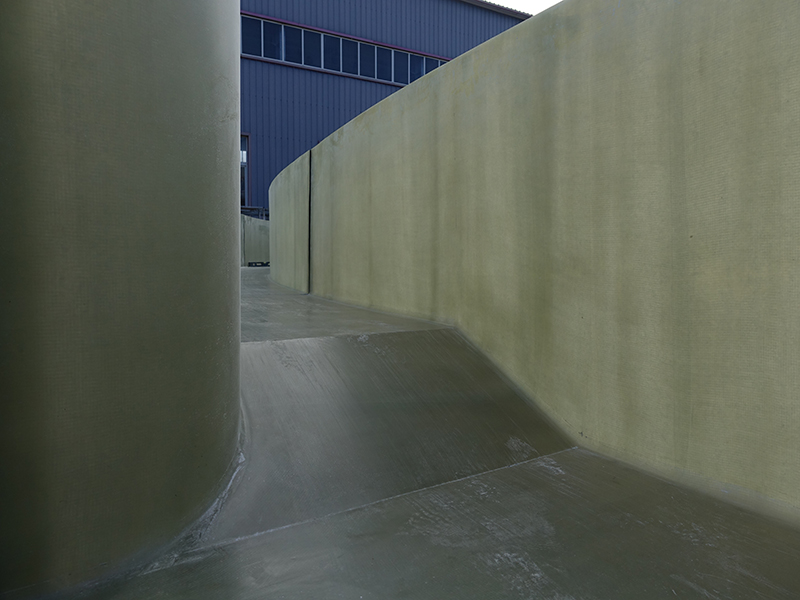

fiberglass products for high temperature

2. Automotive Sector The automotive industry employs fiberglass for engine compartments, exhaust systems, and heat shields. These applications benefit from fiberglass's thermal insulating properties, which protect sensitive components from heat generated by the engine. The lightweight nature of fiberglass also contributes to improved fuel efficiency and performance.

3. Power Generation In the realm of power generation, fiberglass products are utilized in turbines, insulators, and protective covers. Given that power plants often operate at elevated temperatures, the inherent heat resistance of fiberglass is crucial in ensuring the longevity and reliability of these components.

4. Construction and Insulation Fiberglass is also widely used in construction, especially for insulation purposes. Fiberglass insulation helps regulate temperatures within buildings, providing comfort and energy efficiency. Additionally, high-temperature fiberglass boards are used in the manufacturing of fire-resistant panels and thermal barriers.

Advantages of Fiberglass Products

The advantages of fiberglass products extend beyond their temperature resilience. They are lightweight yet strong, resistant to corrosion, and have low thermal conductivity, making them excellent thermal insulators. Furthermore, fiberglass can be molded into complex shapes, allowing for versatility in design and application.

Another significant benefit is the cost-effectiveness of fiberglass compared to other high-temperature materials, such as metals or ceramics. While fiberglass may not have the same level of mechanical strength as metals at elevated temperatures, its advantages in terms of weight, insulation properties, and cost make it a preferred choice for many applications.

Conclusion

Fiberglass products are an indispensable part of modern industry, particularly in high-temperature applications. As technology evolves and the demand for materials that can withstand extreme environments continues to grow, fiberglass is likely to play an even more prominent role. Its unique combination of attributes, including high-temperature resistance, lightweight nature, and versatility, positions it as a key material for the future. As industries embark on this journey of innovation, fiberglass will undoubtedly remain at the forefront, supporting the development of safer, more efficient, and advanced products across various sectors.

Latest news

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025