-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

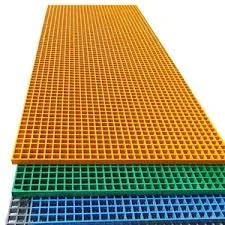

fiberglass products for steel smelting plant

The Role of Fiberglass Products in Steel Smelting Plants

In the modern industrial landscape, steel smelting plants play a crucial role in supporting the infrastructure and technological advancements of societies worldwide. As the demand for steel continues to grow, so does the need for efficient, cost-effective, and sustainable materials in the operational processes. Among these materials, fiberglass products have emerged as indispensable tools in enhancing the efficiency and safety of steel smelting operations. This article explores the innovative applications of fiberglass in steel smelting plants, highlighting its benefits and potential for future advancements.

Understanding Fiberglass

Fiberglass, a composite material made from fine glass fibers, is known for its exceptional strength-to-weight ratio, corrosion resistance, and versatility. These qualities have made fiberglass a popular choice in various industries, including construction, automotive, aerospace, and manufacturing. In the context of steel smelting plants, fiberglass is particularly valued for its ability to withstand high temperatures and its durability in harsh environments.

Application of Fiberglass in Steel Smelting

1. Insulation One of the primary applications of fiberglass in steel smelting plants is thermal insulation. The high temperatures involved in smelting processes necessitate effective insulation materials to prevent heat loss and ensure energy efficiency. Fiberglass insulation reduces heat transfer, helping to maintain optimal temperatures within furnaces and other equipment. This not only maximizes energy usage but also contributes to cost savings in heating operations.

2. Refractory Linings Fiberglass products are also utilized in refractory linings within smelting furnaces. These linings are crucial for protecting the furnace structures from intense heat and corrosion caused by molten steel and slag. The lightweight nature of fiberglass makes it an excellent option for refractory systems, allowing for easier installation and maintenance while providing effective protection against extreme conditions.

fiberglass products for steel smelting plant

3. Structural Components The construction of steel smelting plants involves a wide range of structural components, many of which can benefit from the use of fiberglass. For instance, fiberglass-reinforced plastic (FRP) can be used for beams, columns, and platforms, providing strength and structural integrity with reduced weight. This not only facilitates easier handling and installation but also minimizes the overall energy consumption of the plant's structure.

4. Safety Equipment Safety is paramount in steel smelting operations, where the risk of accidents and exposure to hazardous materials is significant. Fiberglass products offer a solution in the form of safety equipment such as walkways, ladders, and railings. These products are resistant to corrosion and can withstand the harsh chemical environments typical of steel smelting plants, ensuring reliable safety features that protect workers and equipment alike.

5. Environmental Benefits Another critical aspect of utilizing fiberglass in steel smelting is its contribution to environmental sustainability. The lightweight properties of fiberglass can lead to reduced energy consumption during transportation and installation. Moreover, its durability means a longer lifespan for various components, reducing waste and the frequency of replacements. Additionally, fiberglass can be integrated into systems designed to minimize emissions and enhance the overall efficiency of smelting processes, aligning with global sustainability goals.

Future Prospects

As technology continues to evolve, the potential for fiberglass products in steel smelting plants is vast. Innovations in manufacturing processes are likely to yield even more advanced fiberglass composites with enhanced properties, offering improved performance in terms of thermal resistance and structural integrity. Research into more sustainable production methods for fiberglass itself may further bolster its role in environmentally responsible steel production.

Conclusion

Fiberglass products have established themselves as vital components in the operation and maintenance of steel smelting plants. Their characteristics—such as high-temperature resistance, corrosion resistance, and lightweight performance—make them essential for various applications, including insulation, safety equipment, and structural components. As the steel industry moves towards sustainability and efficiency, the role of fiberglass is expected to grow, driving innovations that enhance both operational effectiveness and environmental responsibility. By embracing these advanced materials, steel smelting plants can not only improve their productivity but also contribute positively to a sustainable industrial future.