-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

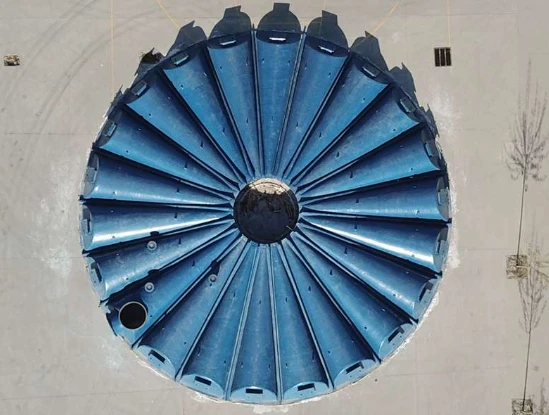

fiberglass products for steel smelting plant

Fiberglass Products for Steel Smelting Plants Enhancing Efficiency and Durability

In the steel industry, the smelting process is crucial for transforming raw iron and other materials into steel. This process involves high temperatures and various corrosive environments, which place tremendous stress on equipment and structures within the smelting plant. To mitigate wear and enhance operational efficiency, fiberglass products have emerged as a significant innovation in this sector.

Understanding the Role of Fiberglass in Steel Smelting

Fiberglass is a composite material made from fine glass fibers and resin. Its remarkable strength-to-weight ratio, high resistance to corrosion, and excellent thermal insulation properties make it an ideal choice for various applications in steel smelting plants. Given the volatile conditions within these facilities, the use of fiberglass products can substantially improve the longevity and reliability of plant equipment.

Applications of Fiberglass Products

1. Insulation and Heat Resistance One of the primary roles of fiberglass in steel smelting plants is insulation. Fiberglass insulation materials can withstand extreme temperatures, ensuring that heat is contained within systems where necessary. This characteristic not only preserves energy but also protects personnel and equipment from heat exposure.

2. Corrosion Resistance The chemical nature of the processes in steel smelting often leads to corrosive environments. Here, fiberglass products, such as grated flooring, walkways, and structural supports, come into play. These materials resist deterioration from acidic compounds and other corrosive agents, ensuring that infrastructure lasts longer and requires less maintenance.

3. Structural Components Fiberglass-reinforced plastic (FRP) can be molded into various shapes and sizes, making it suitable for custom structural components in a smelting plant. This versatility allows engineers to design specific parts that can withstand the unique demands of their operations, from equipment housings to pipeline systems.

fiberglass products for steel smelting plant

4. Safety Features Safety is paramount in steel smelting facilities where heavy machinery and molten materials coexist. Fiberglass products can enhance safety in several ways. For example, fiberglass ladders and platforms are lightweight yet strong, reducing the risk of accidents during maintenance tasks. Additionally, their non-conductive properties make them a safer alternative in environments where electrical hazards might exist.

Advantages of Using Fiberglass in Steel Smelting Plants

The benefits of incorporating fiberglass products into steel smelting operations are numerous

- Cost Efficiency Although the initial investment in fiberglass products may be higher than traditional materials, the long-term savings due to lower maintenance and replacement costs can be substantial.

- Environmental Impact With rising concerns over environmental sustainability, fiberglass products help reduce the ecological footprint of steel smelting plants. Their durability means fewer replacements, leading to decreased waste.

- Improved Performance With the adoption of fiberglass materials, steel smelting operations can run more efficiently. Improved insulation helps maintain optimal temperatures, resulting in energy savings and increased output quality.

Conclusion

As the steel industry continues to evolve, the integration of advanced materials like fiberglass is critical for enhancing efficiency, durability, and safety in smelting plants. The unique properties of fiberglass make it an invaluable asset in an environment characterized by extreme conditions. By leveraging these innovations, steel producers can not only streamline operations but also contribute to a more sustainable and safer industrial future. The growth of fiberglass product applications in steel smelting signifies a promising trend toward modernization and improved manufacturing processes in the steel sector.

Latest news

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025