-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Feb . 01, 2025 05:51

Back to list

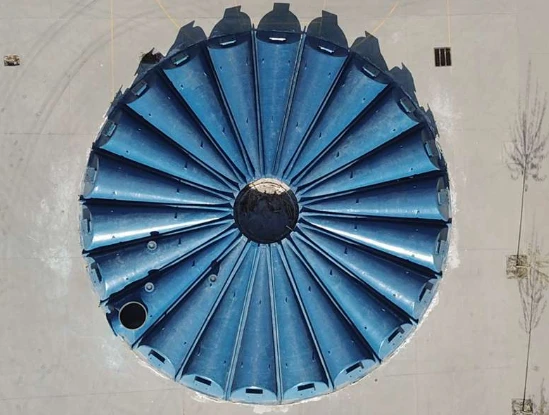

Oblate Tanks

In the realm of steel smelting, fiberglass products stand as unsung heroes, providing crucial support to complex industrial processes. Fiberglass, with its unique properties, offers unparalleled benefits in the demanding environment of steel plants, where intense heat and corrosive materials present significant challenges. As an industry veteran with years of experience, I've witnessed firsthand the transformative role fiberglass products play in enhancing efficiency and safety in steel smelting operations.

Expertise in the selection and application of fiberglass products is crucial. With advancements in manufacturing technologies, today's fiberglass solutions incorporate superior resins and advanced reinforcement technologies, offering enhanced performance over earlier iterations. As someone deeply embedded in the industry, I can attest that partnering with manufacturers who prioritize innovation and quality can yield significant returns on investment. These partnerships ensure that the latest fiberglass technologies are employed to improve operational efficiency while adhering to stringent safety and environmental standards. In terms of environmental impact, fiberglass products offer a sustainable alternative to conventional materials. They are often made from recycled glass and can be recycled at the end of their life cycle, contributing to a reduction in industrial waste. This aligns with the growing emphasis on sustainability in the industrial sector, where steel plants are increasingly under pressure to reduce their carbon footprint. The adoption of fiberglass solutions is a step towards achieving these environmental goals without sacrificing performance. Trustworthiness in product performance is further reinforced by rigorous testing and quality control processes. Reliable suppliers conduct comprehensive assessments to ensure that their fiberglass products meet or exceed industry standards. This level of scrutiny guarantees durability and effectiveness, providing plant operators with the confidence needed to focus on productivity without worrying about material failure. In conclusion, fiberglass products offer an exceptional combination of durability, flexibility, and environmental benefits tailored to the demanding environment of steel smelting plants. Their unique properties deliver demonstrable improvements in efficiency, safety, and sustainability, making them an indispensable asset in modern steel production. By leveraging advanced fiberglass technologies and engaging with knowledgeable suppliers, steel manufacturers can achieve operational excellence and competitive advantage. My extensive experience in this field reinforces the belief that embracing fiberglass solutions is not just a prudent choice; it is a strategic imperative for the future of steel smelting.

Expertise in the selection and application of fiberglass products is crucial. With advancements in manufacturing technologies, today's fiberglass solutions incorporate superior resins and advanced reinforcement technologies, offering enhanced performance over earlier iterations. As someone deeply embedded in the industry, I can attest that partnering with manufacturers who prioritize innovation and quality can yield significant returns on investment. These partnerships ensure that the latest fiberglass technologies are employed to improve operational efficiency while adhering to stringent safety and environmental standards. In terms of environmental impact, fiberglass products offer a sustainable alternative to conventional materials. They are often made from recycled glass and can be recycled at the end of their life cycle, contributing to a reduction in industrial waste. This aligns with the growing emphasis on sustainability in the industrial sector, where steel plants are increasingly under pressure to reduce their carbon footprint. The adoption of fiberglass solutions is a step towards achieving these environmental goals without sacrificing performance. Trustworthiness in product performance is further reinforced by rigorous testing and quality control processes. Reliable suppliers conduct comprehensive assessments to ensure that their fiberglass products meet or exceed industry standards. This level of scrutiny guarantees durability and effectiveness, providing plant operators with the confidence needed to focus on productivity without worrying about material failure. In conclusion, fiberglass products offer an exceptional combination of durability, flexibility, and environmental benefits tailored to the demanding environment of steel smelting plants. Their unique properties deliver demonstrable improvements in efficiency, safety, and sustainability, making them an indispensable asset in modern steel production. By leveraging advanced fiberglass technologies and engaging with knowledgeable suppliers, steel manufacturers can achieve operational excellence and competitive advantage. My extensive experience in this field reinforces the belief that embracing fiberglass solutions is not just a prudent choice; it is a strategic imperative for the future of steel smelting.

Next:

Related Products