-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Feb . 14, 2025 18:42

Back to list

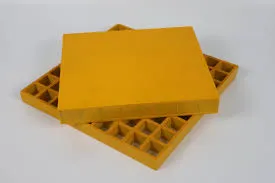

Rectangular Tanks

Fiberglass products have become an integral component in the thermal and nuclear power industries, showcasing an amalgamation of innovation, safety, and efficiency. These industries demand materials that can withstand extreme conditions, such as high temperatures and radiation, while offering long-term durability. Fiberglass, with its unique properties, has risen to meet these rigorous demands.

An often-overlooked benefit of fiberglass in the energy sector is its environmental impact. Fiberglass is recyclable, and its production process is generally more environmentally friendly compared to metals such as steel and aluminum. In an era where carbon footprints and sustainable practices are scrutinized more than ever, choosing materials like fiberglass aligns with global sustainability goals. By integrating fiberglass products, thermal and nuclear power plants can enhance their green credentials, appealing to environmentally conscious stakeholders and consumers. Customization is an additional factor that elevates fiberglass's suitability for power applications. Manufacturers can mold fiberglass into various forms, sizes, and thicknesses, tailoring products to specific plant requirements. This flexibility allows for innovative solutions that can address unique challenges faced in power generation. Whether custom designing a complex ducting system or creating specialized containment units, fiberglass provides the versatility needed to innovate with confidence. The deployability of fiberglass in emergency situations is another testament to its supremacy. In instances where immediate repairs or reinforcements are required, fiberglass can be quickly installed or applied, ensuring that operations continue with minimal interruption. The ease of handling and rapid deployment capabilities of fiberglass make it a strategic asset in maintaining operational continuity in critical settings such as power plants. Fiberglass’s emergence in the thermal and nuclear power sectors encapsulates the perfect blend of modern technology and practical application. Its unrivaled properties make it an irreplaceable resource, driving efficiency, safety, and sustainability. For operators and engineers, investing in fiberglass products is not just about meeting today's demands but preparing for tomorrow's challenges in the ever-evolving landscape of power generation. As we continue to push the boundaries of what is possible in energy production, fiberglass stands out as a material that matches ambition with capability.

An often-overlooked benefit of fiberglass in the energy sector is its environmental impact. Fiberglass is recyclable, and its production process is generally more environmentally friendly compared to metals such as steel and aluminum. In an era where carbon footprints and sustainable practices are scrutinized more than ever, choosing materials like fiberglass aligns with global sustainability goals. By integrating fiberglass products, thermal and nuclear power plants can enhance their green credentials, appealing to environmentally conscious stakeholders and consumers. Customization is an additional factor that elevates fiberglass's suitability for power applications. Manufacturers can mold fiberglass into various forms, sizes, and thicknesses, tailoring products to specific plant requirements. This flexibility allows for innovative solutions that can address unique challenges faced in power generation. Whether custom designing a complex ducting system or creating specialized containment units, fiberglass provides the versatility needed to innovate with confidence. The deployability of fiberglass in emergency situations is another testament to its supremacy. In instances where immediate repairs or reinforcements are required, fiberglass can be quickly installed or applied, ensuring that operations continue with minimal interruption. The ease of handling and rapid deployment capabilities of fiberglass make it a strategic asset in maintaining operational continuity in critical settings such as power plants. Fiberglass’s emergence in the thermal and nuclear power sectors encapsulates the perfect blend of modern technology and practical application. Its unrivaled properties make it an irreplaceable resource, driving efficiency, safety, and sustainability. For operators and engineers, investing in fiberglass products is not just about meeting today's demands but preparing for tomorrow's challenges in the ever-evolving landscape of power generation. As we continue to push the boundaries of what is possible in energy production, fiberglass stands out as a material that matches ambition with capability.

Next:

Related Products