-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

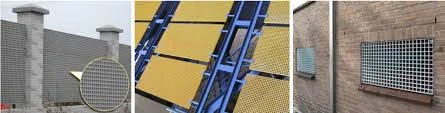

fiberglass reinforced pipe

Fiberglass Reinforced Pipe A Comprehensive Overview

In the realm of modern infrastructure, the choice of materials is paramount to the success and longevity of any project. Among various options available, fiberglass reinforced pipe (FRP) has emerged as a leading choice for applications demanding superior durability, flexibility, and resistance to various environmental conditions. This article delves into the characteristics, benefits, applications, and future prospects of fiberglass reinforced pipes.

Fiberglass reinforced pipe is constructed from a composite material that combines fiberglass and resin. The fiberglass provides tensile strength, while the resin acts as a binding agent, offering resistance to corrosion and environmental challenges. This combination results in a lightweight, yet incredibly strong material, making FRP an ideal option for a myriad of applications, from municipal water systems to industrial processes.

One of the standout features of FRP is its resistance to corrosion. Unlike traditional materials such as steel or concrete, fiberglass does not rust or degrade when exposed to harsh chemicals. This property is particularly beneficial in industries like oil and gas, wastewater treatment, and chemical processing, where pipes are often subjected to corrosive substances. By utilizing FRP, companies can significantly reduce maintenance costs and extend the lifespan of their infrastructure.

In addition to corrosion resistance, fiberglass reinforced pipes offer exceptional flexibility. This characteristic allows for easier installation, particularly in environments with challenging terrain. The lightweight nature of FRP makes transportation and handling more manageable, reducing labor costs and time required for installation. Furthermore, the flexibility of these pipes minimizes the risk of damage during seismic events, making them an optimal choice in earthquake-prone regions.

fiberglass reinforced pipe

Another significant advantage of fiberglass reinforced pipes is their excellent hydraulic performance

. FRP pipes have a smooth internal surface, which minimizes friction losses and enhances flow rates. This feature is crucial in applications requiring efficient water transport, as it can lead to lower energy consumption and reduced operational costs.The versatility of fiberglass reinforced pipes extends to various configurations and sizes, making them suitable for a wide range of applications. FRP is used in municipal water and wastewater systems, stormwater management, industrial fluid transport, as well as in oil and gas pipelines. Moreover, the adaptability of FRP allows for customization to meet specific project requirements, including different bending radii and diameters, further enhancing its appeal in engineering projects.

Sustainability is becoming an increasingly important factor in material selection, and fiberglass reinforced pipes have a positive environmental impact as well. The manufacturing process of FRP is less resource-intensive compared to traditional materials, resulting in a smaller carbon footprint. Additionally, the long-lasting nature of FRP reduces the need for frequent replacements, contributing to lower material waste over time.

Looking to the future, the market for fiberglass reinforced pipes is expected to grow significantly. As industries and municipalities continue to seek durable, cost-effective, and environmentally friendly solutions, the demand for FRP will likely increase. Furthermore, ongoing advancements in manufacturing technologies and materials science may lead to the development of even more resilient and efficient fiberglass reinforced pipes, pushing the boundaries of what these materials can achieve.

In conclusion, fiberglass reinforced pipe stands out as a superior choice for various applications, thanks to its unique properties such as corrosion resistance, flexibility, and excellent hydraulic performance. Its ability to meet the demands of modern infrastructure while minimizing environmental impact positions FRP as a vital material in the construction and utilities sectors. As industries evolve and the need for sustainable solutions intensifies, fiberglass reinforced pipes will undoubtedly continue to play a crucial role in shaping the future of infrastructure development.