-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Feb . 16, 2025 06:51

Back to list

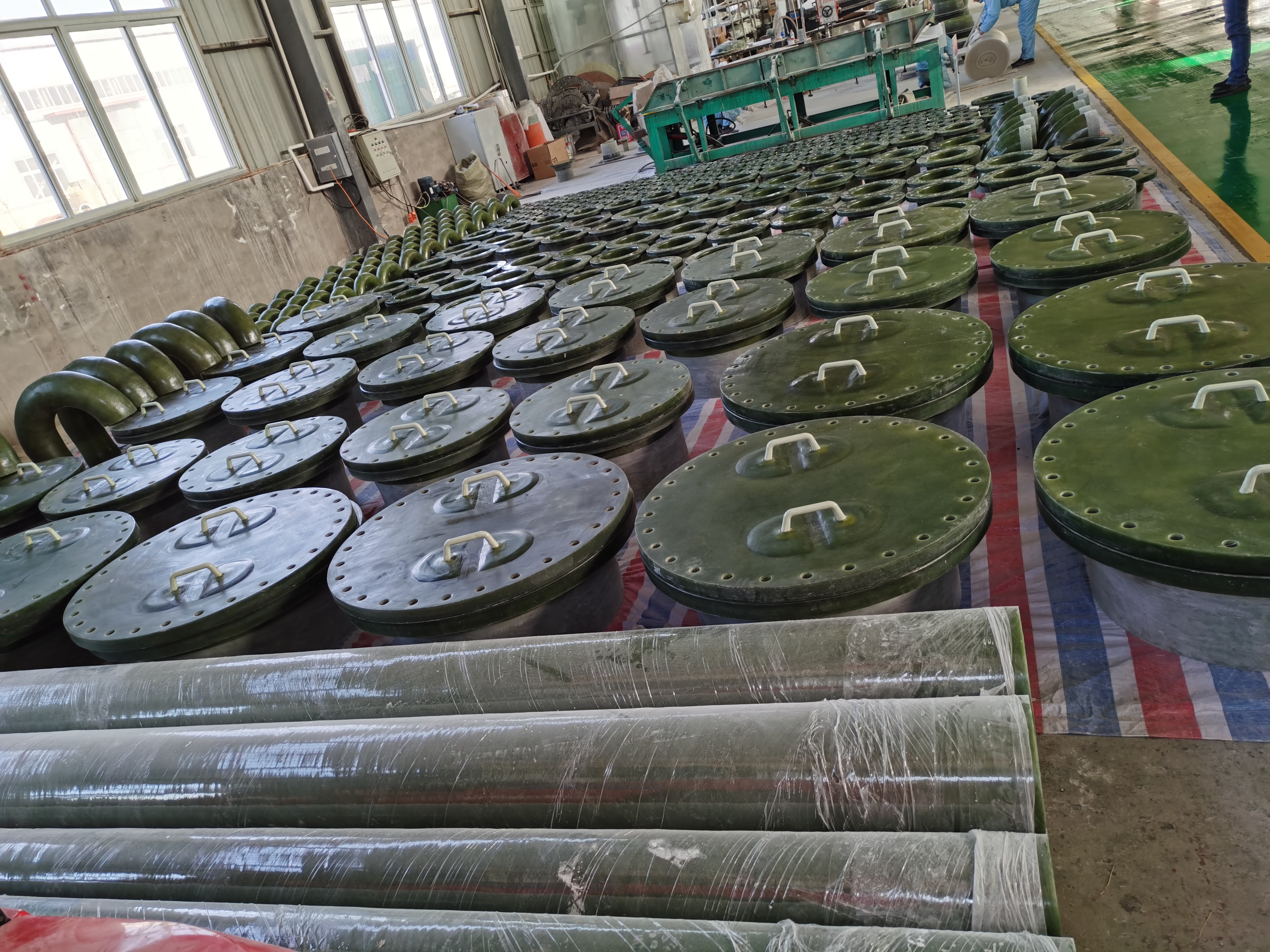

fiberglass reinforced pipe

Fiberglass reinforced pipes (FRP) have rapidly gained traction across various industries, primarily due to their remarkable combination of durability, strength, and resistance to environmental factors. This innovative material is revolutionizing how industries approach fluid transport, offering a sustainable alternative to traditional piping materials like steel and concrete.

A significant advantage of FRP is its adaptability. The modular manufacturing process allows for customization in size, shape, and composition to meet specific requirements, which is particularly beneficial in sectors like construction and infrastructure development. Tunnel linings, bridge supports, and high-pressure water main systems are just a few examples where FRP's customizable properties can be exploited. Economic considerations also favor the adoption of fiberglass reinforced pipes. Despite a potentially higher upfront cost compared to alternatives, the long-term savings from reduced maintenance, longer lifespan, and efficiency in installation often result in a lower total cost of ownership. As industries grow increasingly conscious of lifecycle costs and sustainability, the value proposition of FRP continues to strengthen. To ensure optimal performance, it is crucial for industry professionals to work with experienced manufacturers and installers who understand the complexities and benefits of FRP. Companies specializing in fiberglass technology provide valuable insights and engineering support, leading to optimal design and material selection tailored to specific applications. The advancements in FRP technology further enhance its position as a preferred choice for future-proof infrastructure. Innovations in resin formulations and reinforcement materials are continuously improving its properties, making it an area of keen interest for industry professionals and researchers alike. For companies looking to navigate the challenges of modern industry with efficiency and sustainability, fiberglass reinforced pipes offer a compelling solution. With proven performance across multiple sectors and evolving innovations, FRP emerges as a robust choice for those seeking to align with contemporary demands for durability and environmental responsibility.

A significant advantage of FRP is its adaptability. The modular manufacturing process allows for customization in size, shape, and composition to meet specific requirements, which is particularly beneficial in sectors like construction and infrastructure development. Tunnel linings, bridge supports, and high-pressure water main systems are just a few examples where FRP's customizable properties can be exploited. Economic considerations also favor the adoption of fiberglass reinforced pipes. Despite a potentially higher upfront cost compared to alternatives, the long-term savings from reduced maintenance, longer lifespan, and efficiency in installation often result in a lower total cost of ownership. As industries grow increasingly conscious of lifecycle costs and sustainability, the value proposition of FRP continues to strengthen. To ensure optimal performance, it is crucial for industry professionals to work with experienced manufacturers and installers who understand the complexities and benefits of FRP. Companies specializing in fiberglass technology provide valuable insights and engineering support, leading to optimal design and material selection tailored to specific applications. The advancements in FRP technology further enhance its position as a preferred choice for future-proof infrastructure. Innovations in resin formulations and reinforcement materials are continuously improving its properties, making it an area of keen interest for industry professionals and researchers alike. For companies looking to navigate the challenges of modern industry with efficiency and sustainability, fiberglass reinforced pipes offer a compelling solution. With proven performance across multiple sectors and evolving innovations, FRP emerges as a robust choice for those seeking to align with contemporary demands for durability and environmental responsibility.

Related Products