-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

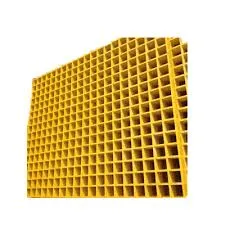

Durable Composite Tanks Made from Fiberglass Reinforced Plastic for Various Applications

Understanding Fiberglass Reinforced Plastic Tanks

Fiberglass reinforced plastic (FRP) tanks have become increasingly important in various industries due to their durability, lightweight nature, and resistance to corrosion and chemicals. These tanks combine the flexibility of plastic with the strength of fiberglass, making them suitable for a wide range of applications, from water storage to chemical processing. Understanding the benefits, applications, and maintenance of FRP tanks can aid in making informed decisions for businesses and organizations.

What is Fiberglass Reinforced Plastic?

Fiberglass reinforced plastic is a composite material made of a polymer matrix reinforced with fiberglass. The combination provides a superior strength-to-weight ratio compared to traditional materials like steel or concrete. The plastic acts as a matrix that binds the fibers together, while the fiberglass adds tensile strength, thereby minimizing the risk of breakage and enhancing durability.

Key Benefits of FRP Tanks

1. Corrosion Resistance One of the most significant advantages of FRP tanks is their resistance to corrosion. Unlike traditional metal tanks that can rust when exposed to harsh chemicals or environmental conditions, FRP tanks maintain their integrity over time, making them ideal for storing chemicals, wastewater, and other aggressive substances.

2. Lightweight FRP tanks are significantly lighter than their metal or concrete counterparts. This characteristic not only simplifies transportation and installation but also reduces the structural support requirements in facilities, which consequently lowers construction costs.

3. Customizability Fiberglass reinforced plastic can be molded into various shapes and sizes, allowing for custom designs that fit specific needs. Manufacturers can tailor the thickness of the tanks and incorporate various fittings and accessories as required.

4. Thermal Insulation FRP tanks provide excellent thermal insulation, making them suitable for applications that require controlled temperatures. This property is particularly beneficial in industries such as agriculture and food processing, where maintaining specific temperature ranges is crucial.

5. Longevity With proper care and maintenance, FRP tanks can last for decades. Their durability means fewer replacements are needed over time, which can result in significant cost savings for businesses.

fiberglass reinforced plastic tank

Common Applications of FRP Tanks

Fiberglass reinforced plastic tanks are utilized across a variety of industries. Some common applications include

- Water Treatment FRP tanks are widely used in water treatment facilities for storing potable water, wastewater, and treatment chemicals. Their resistance to corrosion ensures that they do not leach harmful substances into the water.

- Chemical Storage Many industries that handle corrosive chemicals, such as chemicals, pharmaceuticals, and agriculture, rely on FRP tanks for safe storage and processing.

- Food and Beverage In the food industry, FRP tanks can store various liquids, including juices, oils, and dairy products. Their non-reactive nature ensures that the quality of the stored products remains intact.

- Fuel Storage FRP tanks are increasingly used for storing fuels and other hazardous materials, thanks to their ability to prevent leaks and spills.

Maintenance and Lifespan

While FRP tanks are low-maintenance, periodic inspections are recommended to ensure their longevity. Regular checks for signs of wear, such as cracks or degradation, can help identify issues before they become serious problems. Additionally, cleaning the tanks to remove any buildup of residues can maintain their performance and appearance.

Conclusion

In conclusion, fiberglass reinforced plastic tanks provide an array of benefits that make them an excellent choice for various industries. Their combination of lightweight strength, corrosion resistance, and customizability offers advantages that traditional materials cannot match. As industries continue to search for efficient, durable, and safe solutions for liquid storage, FRP tanks are likely to play a pivotal role in modern infrastructure. By understanding their applications and maintenance needs, businesses can leverage these tanks to improve efficiency and safety in their operations.

Latest news

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025