-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Jan . 14, 2025 10:15

Back to list

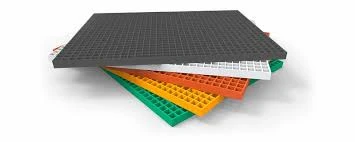

fiberglass settler

In the realm of water and wastewater treatment, the term fiberglass settler has emerged as a transformative concept. As an SEO specialist with extensive experience, let's delve into why fiberglass settlers are making waves and how they are revolutionizing the industry.

The trustworthiness of fiberglass settlers is further grounded in their track record within the industry. Numerous case studies have documented the successful implementation of fiberglass settlers in diverse geographical locations and environmental conditions. These real-world applications have demonstrated their performance in maximizing operational efficiency while minimizing environmental impact. Trust is also built through rigorous quality control processes that govern the manufacturing of fiberglass units, ensuring that every settler meets uncompromising standards of safety and performance. Incorporating fiberglass settlers into a treatment operation can serve as a game-changer. Their lightweight nature compared to traditional materials facilitates easier installation and maintenance, leading to reduced downtime and operational disruptions. Furthermore, the sustainable nature of fiberglass, being recyclable and reducing ecological footprints, aligns with the growing movement towards environmentally conscious industrial practices. In conclusion, the integration of fiberglass settlers represents a significant leap forward in the field of water treatment. By leveraging their unparalleled durability, efficiency, and cost-effectiveness, organizations can ensure continued compliance with regulatory demands while optimizing their operational performance. As always, making informed decisions backed by expert advice and proven technology will remain key to reaping the full benefits that fiberglass settlers have to offer.

The trustworthiness of fiberglass settlers is further grounded in their track record within the industry. Numerous case studies have documented the successful implementation of fiberglass settlers in diverse geographical locations and environmental conditions. These real-world applications have demonstrated their performance in maximizing operational efficiency while minimizing environmental impact. Trust is also built through rigorous quality control processes that govern the manufacturing of fiberglass units, ensuring that every settler meets uncompromising standards of safety and performance. Incorporating fiberglass settlers into a treatment operation can serve as a game-changer. Their lightweight nature compared to traditional materials facilitates easier installation and maintenance, leading to reduced downtime and operational disruptions. Furthermore, the sustainable nature of fiberglass, being recyclable and reducing ecological footprints, aligns with the growing movement towards environmentally conscious industrial practices. In conclusion, the integration of fiberglass settlers represents a significant leap forward in the field of water treatment. By leveraging their unparalleled durability, efficiency, and cost-effectiveness, organizations can ensure continued compliance with regulatory demands while optimizing their operational performance. As always, making informed decisions backed by expert advice and proven technology will remain key to reaping the full benefits that fiberglass settlers have to offer.

Related Products

Latest news

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025