-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Jan . 20, 2025 04:26

Back to list

Transport Tanks

Navigating the innovative landscape of infrastructure materials, fiberglass sewer pipes have emerged as a robust solution for modern sewage systems. As urban areas expand and the demands on sewage systems intensify, the quest for materials that balance durability, performance, and cost-effectiveness is paramount. Here, we delve into the nuances of fiberglass sewer pipes, exploring their benefits, applications, and the expertise underpinning their use.

Such benefits in durability and maintenance are accompanied by fiberglass pipes' flexibility in design and manufacturing. They can be tailored to meet specific project demands, whether it’s for varying diameters, pressure ratings, or custom fittings, ensuring seamless integration into existing systems. This adaptability is an expert's choice for bespoke solutions required in complex urban environments, where space and integration within older infrastructures pose significant challenges. The credibility of fiberglass sewer pipes is reinforced through rigorous testing and certification from esteemed industry standards. Numerous case studies underscore their performance, validated by governmental bodies and independent testing facilities that certify their compliance with global safety and environmental regulations. Such authoritative endorsements instill confidence in stakeholders, from contractors to end-users, fostering trust in fiberglass as a material of choice for sewage infrastructure. Furthermore, the environmental impact of materials is a critical consideration in today's sustainability-focused world. Fiberglass pipes are inherently more sustainable due to their longevity and reduced need for frequent replacements. The manufacturing process of fiberglass is also evolving, with advances leading to lower emissions and decreased environmental footprint, aligning with broader environmental goals and policies. In conclusion, fiberglass sewer pipes represent a sophisticated integration of modern material science with the practical demands of urban infrastructure. Their deployment is not just about meeting current needs but about paving the way for future developments that prioritize durability, efficiency, and sustainability. For project managers, civil engineers, and procurement officials, the choice of fiberglass sewer pipes is a testament to informed decision-making backed by comprehensive understanding and authoritative validation.

Such benefits in durability and maintenance are accompanied by fiberglass pipes' flexibility in design and manufacturing. They can be tailored to meet specific project demands, whether it’s for varying diameters, pressure ratings, or custom fittings, ensuring seamless integration into existing systems. This adaptability is an expert's choice for bespoke solutions required in complex urban environments, where space and integration within older infrastructures pose significant challenges. The credibility of fiberglass sewer pipes is reinforced through rigorous testing and certification from esteemed industry standards. Numerous case studies underscore their performance, validated by governmental bodies and independent testing facilities that certify their compliance with global safety and environmental regulations. Such authoritative endorsements instill confidence in stakeholders, from contractors to end-users, fostering trust in fiberglass as a material of choice for sewage infrastructure. Furthermore, the environmental impact of materials is a critical consideration in today's sustainability-focused world. Fiberglass pipes are inherently more sustainable due to their longevity and reduced need for frequent replacements. The manufacturing process of fiberglass is also evolving, with advances leading to lower emissions and decreased environmental footprint, aligning with broader environmental goals and policies. In conclusion, fiberglass sewer pipes represent a sophisticated integration of modern material science with the practical demands of urban infrastructure. Their deployment is not just about meeting current needs but about paving the way for future developments that prioritize durability, efficiency, and sustainability. For project managers, civil engineers, and procurement officials, the choice of fiberglass sewer pipes is a testament to informed decision-making backed by comprehensive understanding and authoritative validation.

Next:

Related Products

Latest news

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

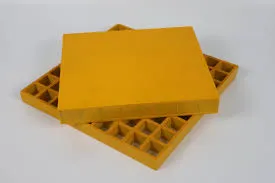

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025