-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Alternative Options for Sewer Pipes Made from Fiberglass Materials

Alternatives to Fiberglass Sewer Pipes Exploring Options for Modern Plumbing Systems

In recent years, the plumbing industry has seen a growing interest in alternatives to traditional materials, including fiberglass sewer pipes. While fiberglass offers certain advantages, such as resistance to corrosion and a lightweight design, it is important to consider various alternatives that may better suit specific project requirements. This article will explore some viable alternatives to fiberglass sewer pipes, their advantages, and considerations for selecting the right material.

1. PVC (Polyvinyl Chloride) Pipes

One of the most common alternatives to fiberglass sewer pipes is PVC. This plastic material is widely used in plumbing systems due to its affordability and ease of installation. PVC pipes are resistant to corrosion, chemicals, and biological growth, making them suitable for sewer applications. They are available in various diameters and have a smooth interior surface that allows for efficient flow and reduces the chance of clogs. However, PVC can become brittle over time, especially when exposed to intense UV light, making it less suitable for outdoor installations without protective measures.

2. HDPE (High-Density Polyethylene) Pipes

Another popular alternative is HDPE, known for its flexibility and durability. HDPE pipes can withstand harsh environmental conditions and are resistant to both corrosion and impact. Their flexible nature allows them to be installed using trenchless methods, which can significantly reduce installation costs and minimize disruption to the surrounding area. Additionally, HDPE is resistant to root intrusion, a common issue in sewer systems. However, proper installation techniques are crucial to ensure the longevity of HDPE pipes, including the use of appropriate fittings and jointing methods.

3. Concrete Pipes

fiberglass sewer pipe alternative.

For larger sewer systems, concrete pipes are often a favored choice. These pipes are extremely strong and durable, making them capable of handling heavy loads. Concrete pipes have a long lifespan and can be particularly effective in high-pressure applications or underground environments prone to ground movement. While they are not as lightweight as other materials, their robustness ensures they can withstand significant wear over time. However, concrete pipes do require proper jointing techniques to prevent leakage and damage from environmental factors.

4. Ductile Iron Pipes

Ductile iron pipes offer another alternative, particularly in situations where high strength and water-tight joints are necessary. These pipes are known for their resilience and ability to withstand both internal pressure and external forces, making them ideal for various applications, including sewage transport. Ductile iron is naturally resistant to corrosion when properly coated, although it may require more maintenance than some plastic alternatives. The installation of ductile iron pipes is generally more labor-intensive, which can increase overall project costs.

5. Composite Materials

Advancements in technology have led to the development of composite materials that combine the benefits of various substances. These materials typically offer enhanced strength, corrosion resistance, and flexibility. While they can be more expensive than traditional materials like PVC or concrete, their durability can lead to lower maintenance costs and longer lifespans.

Conclusion

When considering alternatives to fiberglass sewer pipes, it is essential to evaluate the specific requirements of the project, including environmental conditions, budget constraints, and long-term maintenance needs. PVC, HDPE, concrete, ductile iron, and composite materials each offer unique advantages that may better serve particular applications in plumbing and sewage systems. Understanding the properties of these materials can help contractors and engineers make informed decisions that will enhance the reliability and efficiency of sewer infrastructures in the long run. As research continues and technology evolves, new and improved materials will likely emerge, allowing for even greater flexibility and performance in plumbing solutions.

Latest news

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

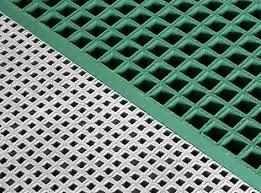

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025