-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Jan . 30, 2025 06:21

Back to list

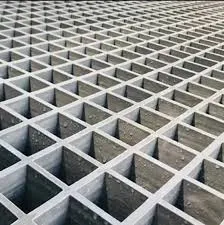

Dual Laminate Products

Fiberglass shells have become a mainstay in various industries due to their unique blend of durability, lightweight properties, and versatility. As the interest in fiberglass products grows, understanding their benefits, applications, and considerations becomes crucial for both consumers and professionals.

It's not just the performance that makes fiberglass shells appealing; their cost-effectiveness also plays a significant role. The manufacturing process of fiberglass is generally less costly compared to alternatives, providing a more economical option for large-scale production and consumers alike. These savings are often passed down to the consumer, making high-performance products more accessible. However, working with fiberglass requires expertise and a deep understanding of its properties to maximize its benefits. Professionals in the field must be knowledgeable about the various grades of fiberglass, curing processes, and the optimal conditions for its application. They must also understand the environmental impact and safety considerations associated with the production and disposal of fiberglass materials. Ensuring that fiberglass products are sustainably made and disposed of is crucial for minimizing their environmental footprint. Moreover, the longevity and performance of fiberglass shells heavily depend on proper maintenance. Regular inspections for cracks or wear and tear can prevent long-term damage and ensure that the material retains its integrity over time. For industries relying on fiberglass for safety, such as automotive or marine, routine maintenance checks are essential. Trust in the quality of fiberglass products comes from reputable manufacturers who prioritize quality control and adhere to industry standards. Certification from recognized bodies provides a layer of assurance to consumers regarding the structural integrity and safety of fiberglass shells. In conclusion, fiberglass shells offer a multitude of benefits across different industries owing to their lightweight, durable, and versatile nature. While they present a cost-effective and high-performance solution, expert handling, and responsible manufacturing practices are essential to harness their full potential. With the proper knowledge and care, fiberglass shells can provide remarkable performance, making them an enduring choice for engineering and design challenges.

It's not just the performance that makes fiberglass shells appealing; their cost-effectiveness also plays a significant role. The manufacturing process of fiberglass is generally less costly compared to alternatives, providing a more economical option for large-scale production and consumers alike. These savings are often passed down to the consumer, making high-performance products more accessible. However, working with fiberglass requires expertise and a deep understanding of its properties to maximize its benefits. Professionals in the field must be knowledgeable about the various grades of fiberglass, curing processes, and the optimal conditions for its application. They must also understand the environmental impact and safety considerations associated with the production and disposal of fiberglass materials. Ensuring that fiberglass products are sustainably made and disposed of is crucial for minimizing their environmental footprint. Moreover, the longevity and performance of fiberglass shells heavily depend on proper maintenance. Regular inspections for cracks or wear and tear can prevent long-term damage and ensure that the material retains its integrity over time. For industries relying on fiberglass for safety, such as automotive or marine, routine maintenance checks are essential. Trust in the quality of fiberglass products comes from reputable manufacturers who prioritize quality control and adhere to industry standards. Certification from recognized bodies provides a layer of assurance to consumers regarding the structural integrity and safety of fiberglass shells. In conclusion, fiberglass shells offer a multitude of benefits across different industries owing to their lightweight, durable, and versatile nature. While they present a cost-effective and high-performance solution, expert handling, and responsible manufacturing practices are essential to harness their full potential. With the proper knowledge and care, fiberglass shells can provide remarkable performance, making them an enduring choice for engineering and design challenges.

Next:

Related Products