-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

fiberglass stack

Understanding Fiberglass Stacks A Comprehensive Overview

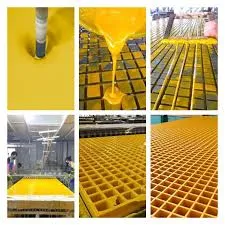

Fiberglass stacks, also known as fibreglass flue stacks or smokestacks, are essential components in various industrial applications, especially in power generation and waste management. These structures, made primarily from fiberglass-reinforced plastic (FRP), serve to vent gases, smoke, and exhaust fumes generated by industrial processes safely into the atmosphere. With growing environmental regulations and a need for sustainable practices, fiberglass stacks have become increasingly popular due to their advantageous properties.

Advantages of Fiberglass Stacks

One of the most significant advantages of fiberglass stacks is their lightweight nature. Unlike traditional materials such as steel or concrete, fiberglass is much lighter, allowing for easier transportation and installation. This lightweight characteristic reduces the load on supporting structures, which can lead to cost savings in the overall construction of industrial complexes.

Moreover, fiberglass stacks exhibit exceptional resistance to corrosion. Industrial emissions often contain harsh chemicals that can deteriorate traditional materials over time. Fiberglass, however, is resistant to a wide range of corrosive substances, making it an ideal choice for environments where chemical exposure is a concern. This durability translates into lower maintenance costs and extended lifespan, providing a better return on investment.

Another key benefit of fiberglass stacks is their thermal insulation properties. They effectively maintain the temperature of exhaust gases, which is critical for the efficiency of many industrial systems. By minimizing heat loss, fiberglass stacks contribute to improved energy efficiency and can help reduce operational costs. This characteristic is particularly beneficial in applications involving high-temperature emissions, such as power plants and incineration facilities.

Design Flexibility

fiberglass stack

Fiberglass stacks also offer a great deal of design flexibility. Manufacturers can produce them in various shapes, sizes, and colors to meet specific aesthetic and functional requirements. This is particularly advantageous for facilities located in areas where visual appeal is essential or for compliance with local regulations regarding the appearance of industrial structures. Customization options enable businesses to maintain a professional image while adhering to safety and environmental standards.

Environmental Considerations

In today’s world, environmental concerns cannot be overlooked. The use of fiberglass stacks contributes to a reduction in emissions, as these stacks can be designed to incorporate advanced filtration and scrubbing technologies. By effectively capturing and venting harmful substances, fiberglass stacks help industries comply with increasingly stringent air quality regulations. This is not only beneficial for the environment but also for the health of nearby communities.

Applications Beyond Industry

While fiberglass stacks are predominantly used in industrial settings, their applications extend to other areas as well. Many commercial buildings utilize fiberglass stacks for HVAC systems, ensuring effective ventilation and air quality control. This versatility highlights the adaptability of fiberglass technology across various sectors, from manufacturing to healthcare and hospitality.

Conclusion

In conclusion, fiberglass stacks have emerged as a vital component in modern industrial infrastructure. Their lightweight, corrosion-resistant nature, combined with thermal efficiency and design versatility, makes them an excellent choice for managing exhaust emissions. As industries continue to strive for sustainability and compliance with environmental regulations, the role of fiberglass stacks will only grow in importance. Manufacturers and facility operators looking to invest in durable and efficient solutions should consider the long-term benefits that fiberglass stacks offer, paving the way for a cleaner, safer industrial future.