-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Feb . 10, 2025 11:43

Back to list

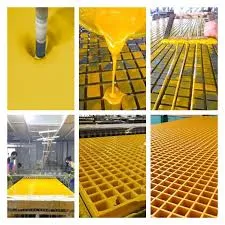

fiberglass stack

Fiberglass stacks are a crucial component in many industrial sectors, offering a versatile solution for emissions control, durability, and efficiency in smoke exhaust systems. These stacks are meticulously crafted using fiberglass-reinforced plastics (FRP), providing robust resistance to a wide range of chemical exposures, temperature variations, and physical stresses. As industries increasingly focus on sustainable practices and emission regulations, the demand for high-quality fiberglass stacks continues to rise.

Furthermore, fiberglass stacks contribute to environmental sustainability. The material is significantly lighter than traditional stack materials like steel or concrete, resulting in reduced energy consumption during transportation and installation. This characteristic not only lowers the carbon footprint but also reduces logistical costs. Moreover, the ease of installation translates into shorter project timelines, decreasing downtime in critical industrial operations. Experts in the field of industrial safety stress the importance of trustworthiness and reliability in material selection for emissions management systems. Fiberglass stacks, with their documented track record in a plethora of applications, provide assurance of reliability. Companies investing in these stacks benefit from extensive research and field data supporting the fiberglass's performance under various environmental conditions, making them a trustworthy choice for long-term operations. For industrial managers considering a transition to fiberglass stacks, it's crucial to engage with suppliers who demonstrate not only expertise in fiberglass technology but also a thorough understanding of specific industrial needs. Suppliers with a proven track record of delivering quality solutions and offering ongoing support become essential partners in achieving operational excellence and compliance. In conclusion, fiberglass stacks represent the intersection of technology, sustainability, and industrial efficiency. Their unique properties offer compelling advantages over traditional materials, from improved durability and compliance to significant logistical and environmental benefits. As industries move towards more sustainable and efficient production practices, investing in fiberglass stacks becomes a sound strategic decision, ensuring both regulatory compliance and operational excellence. By prioritizing quality, customization, and reliability, companies can effectively leverage fiberglass stacks to meet the evolving demands of modern industries.

Furthermore, fiberglass stacks contribute to environmental sustainability. The material is significantly lighter than traditional stack materials like steel or concrete, resulting in reduced energy consumption during transportation and installation. This characteristic not only lowers the carbon footprint but also reduces logistical costs. Moreover, the ease of installation translates into shorter project timelines, decreasing downtime in critical industrial operations. Experts in the field of industrial safety stress the importance of trustworthiness and reliability in material selection for emissions management systems. Fiberglass stacks, with their documented track record in a plethora of applications, provide assurance of reliability. Companies investing in these stacks benefit from extensive research and field data supporting the fiberglass's performance under various environmental conditions, making them a trustworthy choice for long-term operations. For industrial managers considering a transition to fiberglass stacks, it's crucial to engage with suppliers who demonstrate not only expertise in fiberglass technology but also a thorough understanding of specific industrial needs. Suppliers with a proven track record of delivering quality solutions and offering ongoing support become essential partners in achieving operational excellence and compliance. In conclusion, fiberglass stacks represent the intersection of technology, sustainability, and industrial efficiency. Their unique properties offer compelling advantages over traditional materials, from improved durability and compliance to significant logistical and environmental benefits. As industries move towards more sustainable and efficient production practices, investing in fiberglass stacks becomes a sound strategic decision, ensuring both regulatory compliance and operational excellence. By prioritizing quality, customization, and reliability, companies can effectively leverage fiberglass stacks to meet the evolving demands of modern industries.

Next:

Related Products