-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

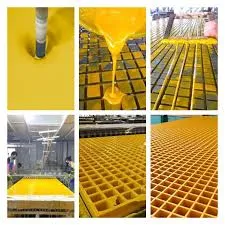

Fiberglass Stack Liner Applications and Benefits for Industrial Emission Control Solutions

The Benefits and Applications of Fiberglass Stack Liners

In the industrial world, efficiency and durability are paramount. One critical aspect of many industrial processes is the management of emissions and the protection of equipment from corrosive environments. This is where fiberglass stack liners come into play. These innovative materials are increasingly being utilized in various applications, providing significant benefits over traditional lining options.

What are Fiberglass Stack Liners?

Fiberglass stack liners are composite products made of reinforced plastic materials, specifically designed to line the interior of industrial stacks, chimneys, and other exhaust systems. These liners are engineered to withstand extreme temperatures and corrosive gases, making them ideal for applications in power plants, waste incinerators, and manufacturing facilities.

Superior Corrosion Resistance

One of the primary advantages of fiberglass stack liners is their superior resistance to corrosion. Traditional materials such as metal and concrete can deteriorate over time when exposed to harsh chemicals and high temperatures. In contrast, fiberglass is inherently resistant to rust, scaling, and chemical reactions, ensuring a longer lifespan and reducing the need for frequent replacements. This property not only enhances the durability of the stacks but also minimizes maintenance costs for operators.

Lightweight and Easy to Install

Fiberglass materials are significantly lighter than conventional lining options, making them easier to handle and install. Reduced weight translates to lower transportation costs and less structural support required for the stacks. Additionally, the installation process for fiberglass liners is typically faster and less labor-intensive. This efficiency is particularly beneficial for industries aiming to minimize downtime during maintenance or upgrades.

Thermal Insulation Properties

fiberglass stack liner

Another prominent feature of fiberglass stack liners is their excellent thermal insulation properties. By reducing heat loss, these liners help improve the overall energy efficiency of the exhaust system. This can lead to decreased fuel consumption and lower operational costs for industries, including power generation facilities that strive for continuous efficiency improvements. In some cases, enhanced insulation can also contribute to reducing greenhouse gas emissions, aligning with global sustainability goals.

Versatile Application Range

Fiberglass stack liners can be used in a variety of applications beyond traditional industrial stacks. They are effective in lining various types of ductwork, process equipment, and even wastewater treatment plants. The versatility of these materials means they can adapt to various operating conditions and environments, from high-temperature settings to chemically aggressive atmospheres.

Environmental Benefits

Investing in fiberglass stack liners can also yield environmental benefits. Given their longevity and resistance to corrosion, these liners help prevent leaks and emissions that could harm the environment. By improving the efficiency of emission control systems, they help industries comply with increasingly stringent environmental regulations. Reducing the environmental footprint of industrial operations is a critical responsibility that fiberglass stack liners facilitate.

Cost-Effectiveness

While the initial investment in fiberglass stack liners may be higher than some traditional options, the long-term savings they provide can make them a more cost-effective solution. Their durability, lower maintenance requirements, and energy-saving properties help businesses offset initial costs over time. Industries are increasingly recognizing that integrating fiberglass technology can lead to significant overall savings and operational efficiencies.

Conclusion

In summary, fiberglass stack liners represent a pinnacle of engineering innovation, offering multiple advantages for various industrial applications. Their corrosion resistance, lightweight nature, thermal insulation properties, and environmental benefits make them an ideal choice for managing exhaust systems and improving overall efficiency. As industries continue to seek sustainable and cost-effective solutions, fiberglass stack liners are sure to play a vital role in transforming how we approach equipment durability and environmental stewardship. Whether in power generation, waste management, or manufacturing, the case for adopting fiberglass stack liners is compelling and increasingly necessary in today’s environmentally-conscious industrial landscape.