-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Composite Materials for High-Performance Stack Liners in Industrial Applications

The Role of Fiberglass Stack Liners in Modern Industrial Applications

In the realm of industrial manufacturing, efficiency and durability are paramount. With stringent regulations on emissions and the need for sustainable manufacturing processes, companies are constantly seeking innovative solutions to improve operational efficiency. One such advancement is the use of fiberglass stack liners, which are proving to be instrumental in enhancing the performance and longevity of flue gas emission systems.

Fiberglass stack liners are composite materials made from glass fibers and resin, designed specifically for use in harsh industrial environments. One of their primary functions is to line the interior of smoke stacks and flue ducts, providing a barrier that protects the structural integrity of these components while managing high temperature and corrosive gases. This is particularly important in industries such as power generation, petrochemicals, and metal processing where emissions can be hazardous and corrosive.

One of the standout features of fiberglass stack liners is their remarkable resistance to corrosion. Traditional stack materials such as metal can suffer from oxidation over time, particularly when exposed to acidic pollutants found in flue gas. Fiberglass, on the other hand, does not corrode, ensuring that operative machinery remains intact and functional for a longer duration. As a result, companies can avoid costly replacement and maintenance expenses, making it a cost-effective solution in the long run.

In addition to their corrosion resistance, fiberglass stack liners are lightweight, which simplifies installation and reduces the load on existing structures. This characteristic can be especially beneficial in retrofitting projects where integrating new materials with old systems is necessary. By using fiberglass, engineers can achieve a more efficient design that minimizes stress on supporting columns and beams, thereby extending the overall lifespan of the infrastructure.

fiberglass stack liner

Thermal stability is another significant advantage of fiberglass stack liners. Many industrial processes generate extreme heat, necessitating materials that can withstand high temperatures without compromising their structural integrity. Fiberglass stack liners are designed to handle these extreme conditions, maintaining their shape and effectiveness even under rapid temperature fluctuations. This thermal resilience not only improves system reliability but also contributes to enhanced operational safety.

Moreover, the use of fiberglass stack liners contributes to improved air quality by reducing emissions. These liners can help achieve better system performance by ensuring proper flow and containment of gases, thus preventing the escape of harmful pollutants. With many industries facing increasing regulatory pressure to adhere to environmental standards, the adoption of fiberglass stack liners can significantly ease compliance challenges.

The ease of maintenance associated with fiberglass stack liners further boosts their appeal. The smooth surface of fiberglass allows for easier cleaning and reduces the accumulation of soot and debris over time. Industries benefit from reduced downtime for maintenance, maximizing productivity, and minimizing operational costs.

To sum up, fiberglass stack liners encapsulate a range of advantages that align with the operational goals of modern industrial practices. Their corrosion resistance, lightweight nature, thermal stability, and enhanced air quality management position them as a superior choice for lining smoke stacks and flue ducts. Not only do they offer long-lasting durability, but they also contribute to a more sustainable approach by reducing emissions and maintenance costs.

As industries continue to evolve and face new environmental challenges, the adoption of innovative materials like fiberglass stack liners serves as a testament to the commitment to operational efficiency, safety, and sustainability. Moving forward, it is likely that we will see a growing trend in the use of these materials, leading the way toward more responsible and resilient industrial practices.

Latest news

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

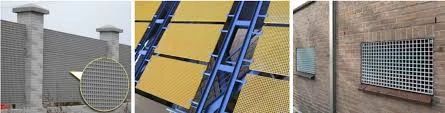

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025