-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Durable Solutions for Water Storage Exploring Fiberglass Tank Benefits and Applications

Fiberglass tanks have become increasingly popular in various industries due to their numerous advantages over traditional storage solutions. These tanks, made from reinforced plastic materials, are widely used for storing water, chemicals, and other liquids. Their application can be traced back to industries such as agriculture, wastewater treatment, and chemical processing, where the need for durable and reliable storage solutions is paramount.

One of the most significant advantages of fiberglass tanks is their corrosion resistance. Unlike metal tanks, which can rust and degrade over time, fiberglass tanks do not succumb to the same kind of wear and tear. This makes them an ideal choice for storing corrosive substances, such as acids and bases, that would otherwise damage conventional storage solutions. The non-reactive nature of fiberglass means that the stored materials remain uncontaminated, ensuring that the integrity of the liquids is maintained.

Moreover, fiberglass tanks are lightweight compared to their metal counterparts. This characteristic simplifies the process of transportation, installation, and maintenance. The reduced weight of fiberglass also means that less structural support is required, which can lower construction costs for installation sites. Additionally, the flexibility of fiberglass allows for a variety of shapes and sizes to be created, catering to specific storage needs and spatial constraints.

Another noteworthy benefit of fiberglass tanks is their longevity. With proper maintenance, these tanks can last for several decades, making them a cost-effective solution over the long term. Their resistance to UV rays and extreme temperatures further enhances their durability, making them suitable for outdoor installations where exposure to the elements is a concern. Regular inspections can easily identify any signs of wear, ensuring that timely maintenance can be performed to extend the tank's lifespan.

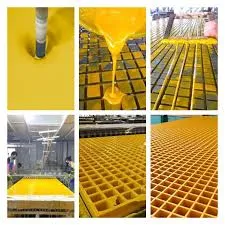

fiberglass tank

In terms of installation, fiberglass tanks are also quite versatile

. They can be installed above ground, partially buried, or fully underground, depending on the space available and the specific requirements of the project. This adaptability is particularly beneficial in locations where space is at a premium, allowing facilities to optimize their storage capabilities without compromising on safety or accessibility.Furthermore, fiberglass tanks come with various features that can enhance their functionality. Many modern designs include built-in inspection ports and manways for easy access, as well as advanced monitoring systems for tracking fluid levels and leak detection. These features contribute to effective management and operational efficiency, making it easier for facility operators to perform necessary checks and maintenance tasks.

Environmental considerations are also paramount in the discussion of fiberglass tanks. Their use can contribute significantly to sustainable practices in water and chemical management. By eliminating the risk of leaks and contamination, fiberglass tanks help protect the surrounding environment from hazardous spills. Additionally, many manufacturers prioritize eco-friendly production methods, making fiberglass an attractive choice for environmentally conscious businesses.

In conclusion, fiberglass tanks offer a myriad of benefits that make them an excellent choice for various liquid storage applications. Their corrosion resistance, lightweight nature, longevity, installation versatility, and environmental considerations position them as a superior alternative to traditional tanks. As industries continue to evolve and seek reliable storage solutions that can withstand the test of time, fiberglass tanks are likely to remain at the forefront of innovation in storage technology. With ongoing advancements in materials and design, the future looks promising for fiberglass tank applications across diverse sectors.