-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Durable and Lightweight Solutions for Storing and Transporting Liquids Using Fiberglass Tanks

The Advancements in Fiberglass Transport Tanks A Modern Solution for Fluid Transport

In the realm of industrial and commercial fluid transport solutions, fiberglass transport tanks have emerged as a preferred choice for many applications due to their unique characteristics and numerous advantages. As industries evolve, the demand for efficient, durable, and cost-effective storage solutions has intensified, making fiberglass tanks an increasingly viable option. This article explores the properties, benefits, applications, and future trends pertaining to fiberglass transport tanks.

Properties of Fiberglass Tanks

Fiberglass, or reinforced plastic, is composed of a polymer matrix supplemented with glass fibers. This composite material combines the lightweight properties of plastics with the strength of glass, making it an ideal choice for various applications, particularly for storing liquids. Fiberglass transport tanks are known for their resistance to corrosion, UV degradation, and chemical reactions, which are critical features when dealing with various fluids, including chemicals, water, and food products.

The manufacturing process of fiberglass tanks involves techniques such as hand lay-up, filament winding, or spray-up processes. These techniques enable the production of tanks in a variety of shapes and sizes, customizable to meet specific needs. Their inherent flexibility allows for the design of tanks that can withstand high pressure and temperature variations, adding to their usability across different environments.

Benefits of Using Fiberglass Transport Tanks

One of the primary advantages of fiberglass transport tanks is their resistance to corrosion. Unlike traditional metal tanks that can suffer from rust and deterioration due to interactions with chemicals, fiberglass tanks maintain their integrity over time. This trait is particularly beneficial for industries handling corrosive materials like acids or salts, where traditional materials would be compromised.

Additionally, fiberglass transport tanks are lightweight, making them easier to handle and transport. This feature not only reduces shipping costs but also facilitates easier installation. The reduced weight can lead to lower transportation expenses, especially for bulk shipping and installation on-site.

Another significant benefit is the longevity and durability of fiberglass tanks. With proper maintenance, these tanks can last for several decades, leading to lower long-term costs compared to other materials that may require frequent replacements. Furthermore, the design flexibility means that companies can design tanks that fit into specific spaces, maximizing storage efficiency.

fiberglass transport tank

Applications of Fiberglass Transport Tanks

Fiberglass transport tanks are employed in various sectors, including agriculture, water treatment, chemical processing, and food and beverage storage. In agriculture, for instance, fiberglass tanks are used to store fertilizers, pesticides, and other chemicals safely. They provide a reliable solution for farmers needing to store potentially harmful substances while ensuring environmental safety.

In the water treatment industry, fiberglass tanks are instrumental in both the storage and transport of water and wastewater, ensuring that exposure to corrosive influences is minimized. Similarly, industries dealing with chemicals benefit significantly from using fiberglass tanks, as they can safely store and transport hazardous materials without the risk of leakage or contamination.

Food and beverage industries utilize fiberglass tanks for storing liquids like juice, milk, or beer, where hygiene and safety are paramount. The smooth surface of fiberglass minimizes bacteria growth and is easy to clean, making it suitable for food-grade applications.

Future Trends

As technology advances, the fiberglass tank manufacturing process is expected to innovate further, leading to even more robust and efficient designs. With an emphasis on sustainability, future trends may include the development of eco-friendly fiberglass materials that reduce environmental impact during production and disposal.

Moreover, smart technology integration is likely to become more commonplace, enabling remote monitoring of tank conditions such as temperature, pressure, and liquid levels. This innovation will improve operational efficiency and safety, providing real-time data crucial for maintaining optimal conditions.

In conclusion, fiberglass transport tanks represent a modern solution to fluid storage and transport challenges. With continuous advancements in materials and technology, their versatility, durability, and efficiency will likely ensure their prominent role across varied industries in the years to come. As companies increasingly prioritize sustainability and cost-effectiveness, fiberglass tanks are poised to become essential components in the fluid transport landscape.

Latest news

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

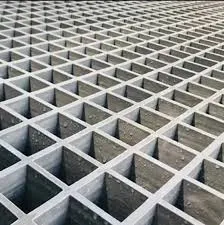

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025